Asphalt shingles are a popular roofing material known for their durability, versatility, and cost-effectiveness. However, understanding the full breakdown of asphalt shingle construction is critical for both manufacturers and consumers. In this blog, we’ll delve into the intricate details of asphalt shingle construction, exploring the number of layers, materials, and production processes involved.

Our company is located in Gulin Industrial Park, Binhai New Area, Tianjin, and is committed to producing high-quality asphalt shingles. We have a factory covering an area of 30,000 square meters and 100 skilled workers with a total investment of RMB 50,000,000 to ensure the excellence of our products. Equipped with two automated production lines, we are capable of meeting large-scale demands while maintaining excellent quality.

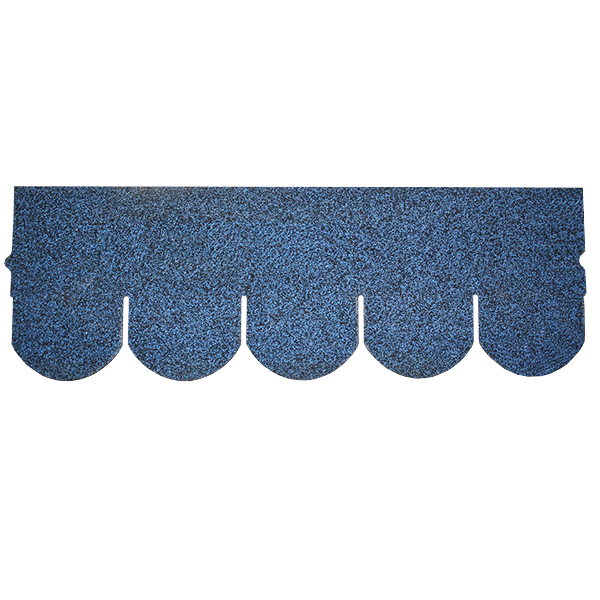

The asphalt shingles offered by us are of fish scale type and are known for their unique aesthetic appeal and superior performance. With FOB prices of US$3-5 per square meter, minimum order quantity of 500 square meters, and monthly supply capacity of 300,000 square meters, we ensure that our products are within reach and ready to use. We operate from Tianjin Xingang Port and offer flexible payment methods, including sight letters of credit and wire transfers, to provide customers with convenient transactions. Our asphalt shingles are carefully packed with 3.1 square meters per bundle, 21 pieces per bundle, and 1020 bundles per 20-foot container to ensure safe and efficient transportation.

Now, let’s discuss a comprehensive breakdown of asphalt shingle construction.

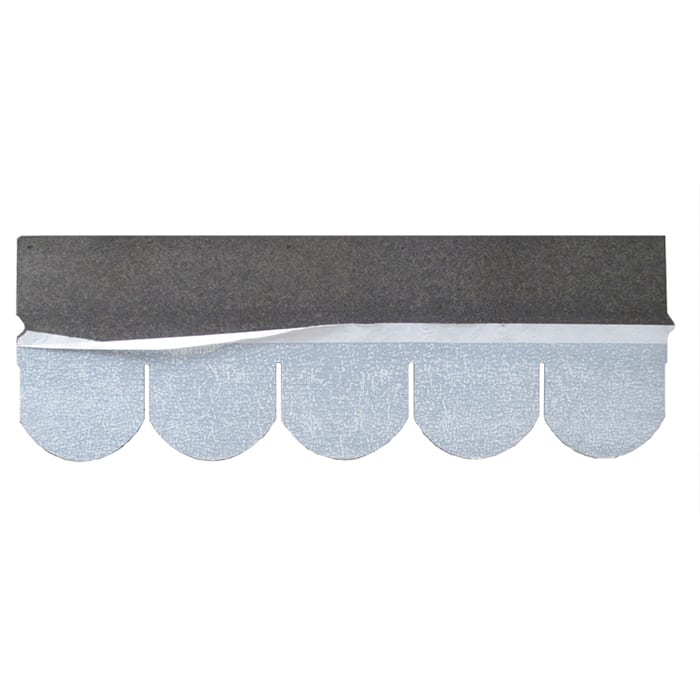

The base layer of asphalt shingles is typically made of fiberglass mat, which provides strength and stability to the shingles. This layer is coated with bitumen, which acts as a waterproofing agent and adhesive. Ceramic particles are then embedded in the asphalt, which not only enhances the shingle's aesthetics but also provides protection against UV rays and harsh weather conditions.

The surface of the tile granules is also coated with a sealant strip to ensure the adhesion between the tiles and provide an additional layer of weatherproof protection. The overlapping design of the shingles creates a barrier that effectively directs water away from the roof, preventing leaks and water damage.

The production process of asphalt shingles involves precision and expertise. Materials are carefully selected and processed to meet industry standards and regulatory requirements. Our state-of-the-art production line ensures each shingle is manufactured with precision and consistency, guaranteeing a high-quality end product.

In summary, a comprehensive breakdown of asphalt shingle construction includes meticulous material layering, precise production processes, and a commitment to quality. As an industry-leading manufacturer, our company is committed to providing top-notch asphalt shingles to meet the diverse needs of our customers. Whether it's a residential, commercial or industrial application, our fish scale asphalt shingle roofs deliver durability, performance and beauty. Explore the world of asphalt shingle construction with us and discover the unparalleled quality and reliability of our products.

Post time: Jul-30-2024