Asphalt shingles are a popular roofing material known for their durability, affordability, and ease of installation. They are made from a combination of bitumen and fillers, with the surface material usually in the form of colored mineral particles. Not only are these particles aesthetically pleasing, they also protect against impact, UV degradation and improve fire resistance.

Materials used in asphalt shingles

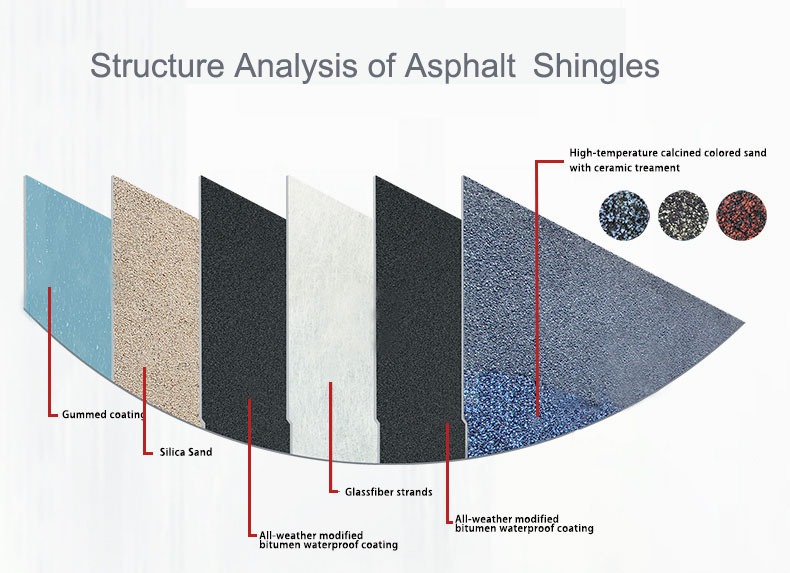

The production of asphalt shingles involves the use of high-quality materials to ensure their longevity and performance. The main ingredients include asphalt, which acts as a binder, and fillers such as limestone, dolomite and fiberglass. The materials are carefully selected for strength, flexibility and weather resistance.

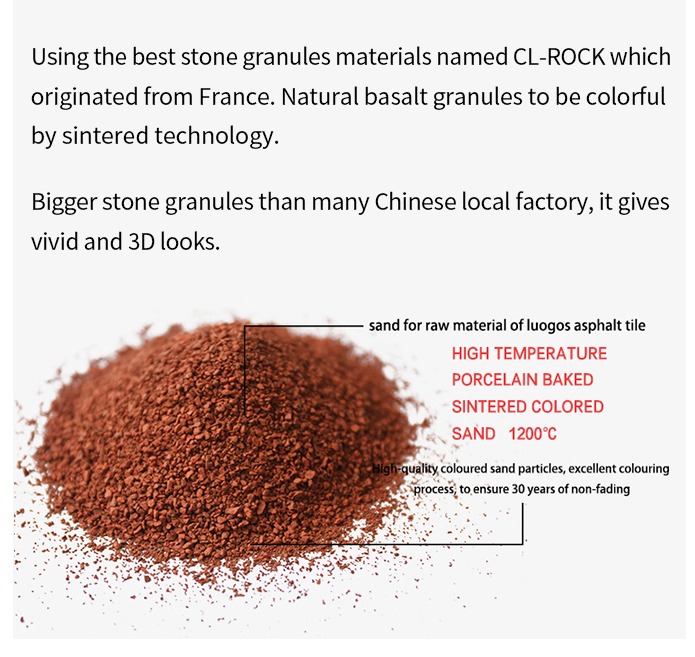

In addition to asphalt and filler, decking materials play a vital role in enhancing the protective properties of shingles. Colored mineral particles are often used to provide UV protection, impact resistance and flame retardancy. Companies like ours use high-temperature sintered basalt particles, which provide superior protection and durability compared to traditional materials.

Asphalt shingle lifespan

The lifespan of asphalt shingles will vary based on a variety of factors, including material quality, installation, and environmental conditions. On average, asphalt shingles have a lifespan of 15 to 30 years, making them a long-lasting roofing option for residential and commercial properties. Proper maintenance and regular inspections can help extend the life of your asphalt shingles, ensuring they continue to provide reliable protection for years to come.

Production process and capabilities

Behind the production of asphalt shingles is a meticulous process that requires precision and expertise. Our company proudly operates the largest production line with an annual output of 30,000,000 square meters while maintaining the lowest energy costs. This high production capacity allows us to meet the growing demand for high-quality asphalt shingles while minimizing our impact on the environment.

The production process involves carefully mixing asphalt, fillers and other additives to create a homogeneous mixture. This mixture is then fed into a production line, where it is formed into shingles, coated with surface material, and cut to the desired size. Our state-of-the-art facility ensures that every shingle meets the highest quality and performance standards.

In summary, understanding the materials, lifespan, and production processes of asphalt shingles is critical for both consumers and industry professionals. By utilizing high-quality materials and advanced production capabilities, the company can provide durable and reliable roofing solutions for a variety of applications. Whether it’s protecting a home from natural disasters or enhancing the aesthetics of a commercial building, asphalt shingles continue to be the roofing industry’s top choice.

Post time: Aug-13-2024