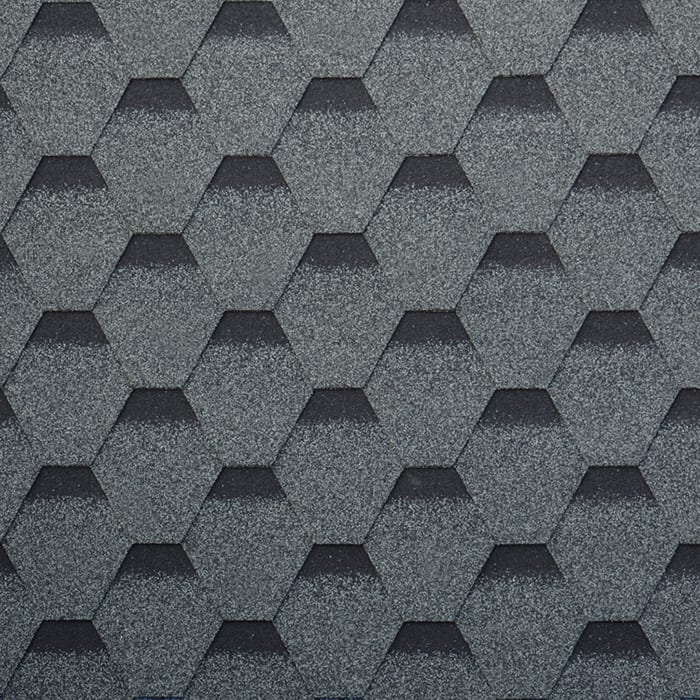

3-Tab Bitumen Shingle: Pricelist & Features for Your Next Project

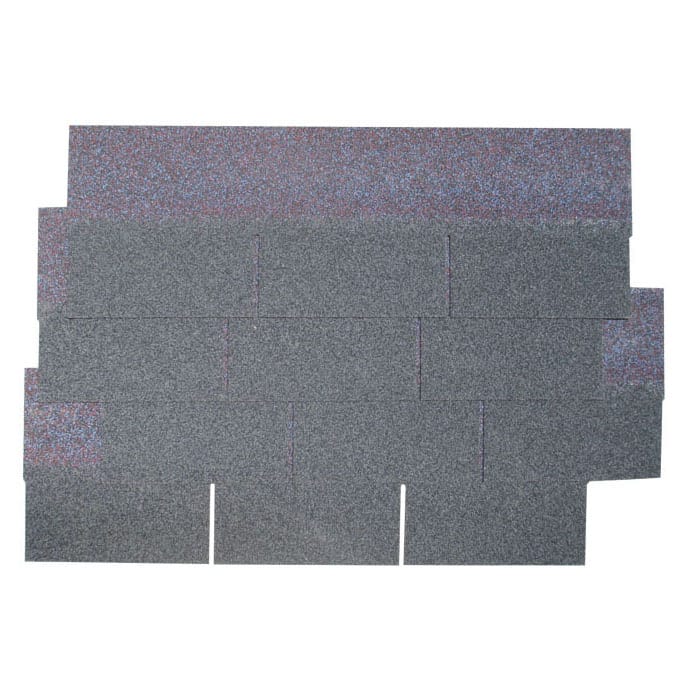

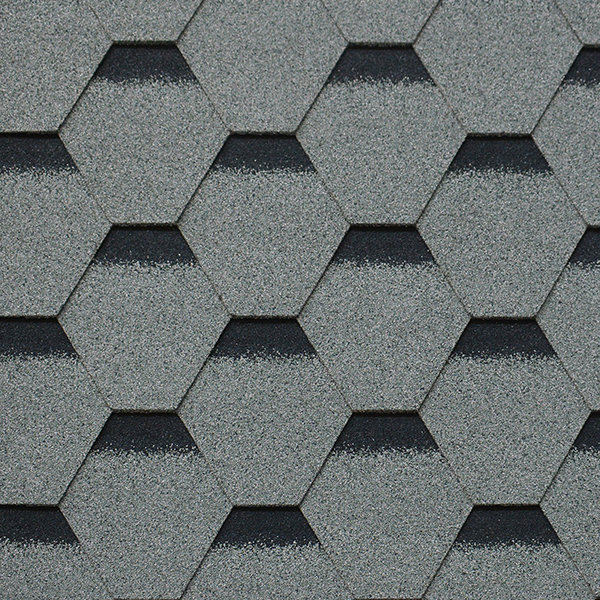

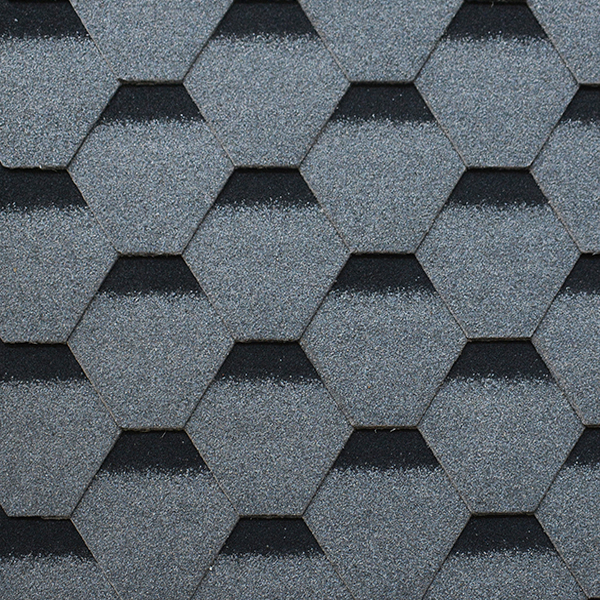

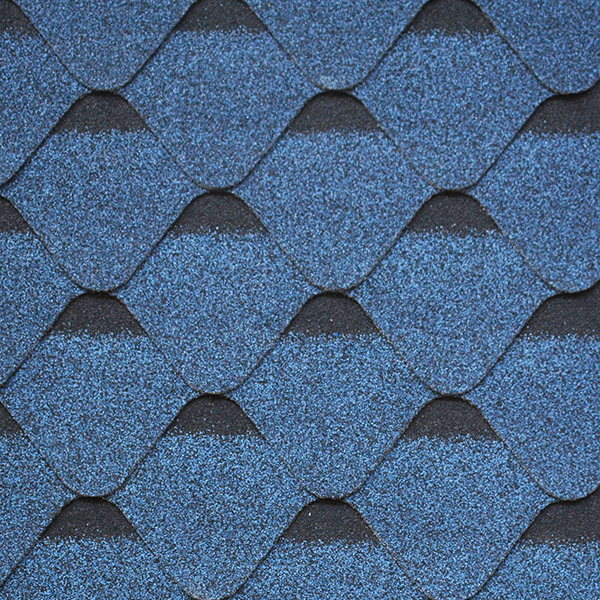

When it comes to roofing solutions, I highly recommend 3-Tab Bitumen Shingles for their unmatched quality and durability. If you're considering a reliable roofing option for your next project, these shingles offer great value and performance. With their unique design, they provide excellent weather resistance and are easy to install, making them a favorite for both contractors and homeowners alike. I understand that pricing is crucial in your decision-making process. That’s why I encourage you to check out our comprehensive pricelist, which outlines competitive rates for bulk purchases. You’ll find these shingles not only meet your technical requirements but also align with your budget. Choosing the right roofing material is essential for long-term satisfaction, and I believe our 3-Tab Bitumen Shingles will exceed your expectations. Don’t hesitate to reach out if you have any questions or need guidance—let's make your project a success together!

3-Tab Bitumen Shingle Factory From Concept to Delivery

When it comes to roofing materials, 3-tab bitumen shingles represent a perfect blend of durability, affordability, and versatility. The journey from concept to delivery of these high-quality shingles involves meticulous planning and execution. Each phase of the manufacturing process is designed to guarantee the final product meets stringent quality standards while catering to the diverse needs of global markets. The initial concept phase focuses on innovative design and material selection, ensuring that the shingles not only protect but also enhance the aesthetic appeal of buildings. As production begins, our state-of-the-art factories utilize advanced technologies and skilled craftsmanship to create shingles that withstand the test of time. Quality control measures are ingrained at every step, from raw material procurement to final assembly. The result is a product that not only meets international standards but also offers endless design possibilities for architects and builders alike. Finally, the delivery process is streamlined to ensure that customers receive their orders promptly and in perfect condition. By fostering strong partnerships with logistics providers, we ensure that our products can be shipped globally, reaching buyers when and where they need them. This commitment to quality and efficiency solidifies our position as a trusted supplier in the roofing industry, catering to a worldwide clientele seeking reliable and stylish roofing solutions.

3-Tab Bitumen Shingle Factory From Concept to Delivery

| Phase | Description | Duration | Key Activities |

|---|---|---|---|

| 1. Concept Development | Initial planning and design of the shingle production process. | 2 months | Market research, feasibility studies, and design blueprint creation. |

| 2. Facility Design | Designing the layout and specifications of the manufacturing facility. | 3 months | Architectural designs, machinery selection, and space planning. |

| 3. Construction | Building the manufacturing facility based on the approved designs. | 6 months | Site preparation, construction, and inspections. |

| 4. Equipment Installation | Installing machinery and production lines needed for shingle production. | 4 months | Installation, calibration, and testing of production equipment. |

| 5. Production Testing | Initial runs of the product to ensure quality and efficiency. | 1 month | Quality assurance tests and adjustments to production parameters. |

| 6. Launch | Official start of manufacturing and distribution of shingles. | 1 month | Marketing campaign and distribution network establishment. |

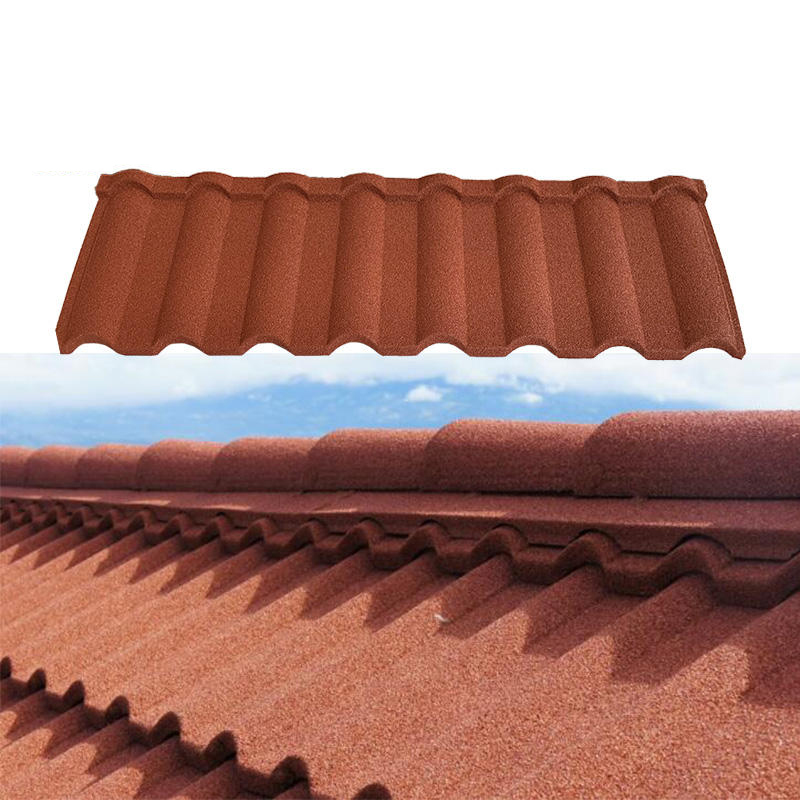

Related Products

3-Tab Bitumen Shingle in 2025 Service Backed by Expertise

Top Selling Products

-

Phone

-

E-Mail

-

Whatsapp