HDPE membrane

Eco-Friendly 1.5mm HDPE membrane

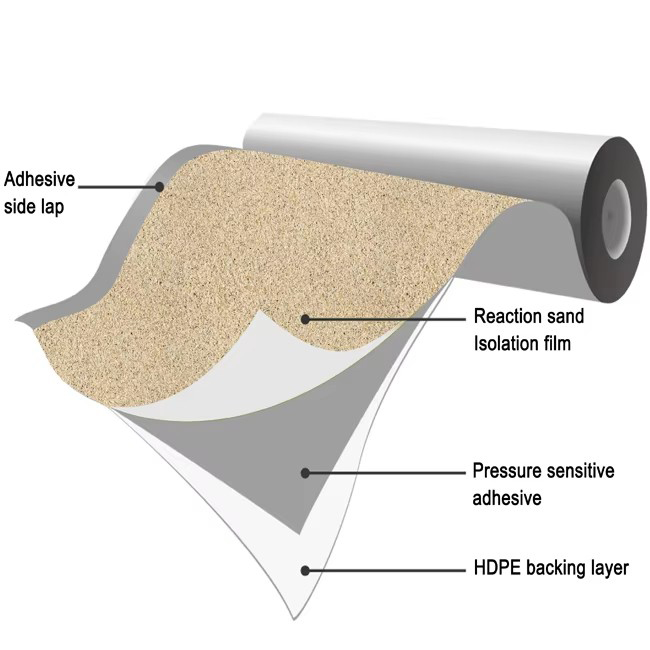

The polymer self-adhesive waterproof membrane is a waterproof membrane composed of polymer sheets, isolation membranes (or pressure-sensitive polymer adhesive layers and uniquely formulated particle layers). This membrane combines the advantages of polymer waterproof membranes and self-adhesive waterproof membranes. It not only has high puncture resistance, weather resistance, high and low temperature resistance, and self-healing properties, but also adopts the pre-laid reverse bonding method, which can react and bond with concrete slurry to form a seamless combination of the waterproof layer and the concrete structure, eliminating interlayer water seepage and effectively improving the reliability of the waterproof system.

HDPE Waterproofing Membrane Specification

|

Product Name

|

HDPE Waterproofing Membrane |

|

Thickness

|

1.2mm 1.5mm 2.0mm or customized

|

|

Width

|

1m-2m or customized

|

| Length |

20m or customized

|

| MOQ |

1000 square meters

|

|

Application Method

|

Pre-paved anti-adhesive

|

Product Sort:

② High aging resistance, UV resistance, corrosion resistance and erosion resistance.

③ Good cold flexibility (-25℃)

Structure Diagram

HDPE Waterproofing Membrane Standard

|

No. |

Item |

Standard |

|

|

1 |

Tensile Property |

Tensile force/ (N/50mm) ≥ |

600 |

|

Tensile Strength/ Mpa ≥ |

16 |

||

|

Elongation Rate are breacking/ % ≥ |

400 |

||

|

2 |

Tear strength of nails rod/ N ≥ |

400 |

|

|

3 |

Puncture resistance strength/ N ≥ |

350 |

|

|

4 |

Anti-impact property/ (0.5kg, m) |

No seepage |

|

|

5 |

Anti-static load |

20kg, No seepage |

|

|

6 |

Heat resistance (80℃, 2h) |

No slipping, flowing or dropping |

|

|

7 |

Low-temperature bending property (-35℃) |

No cracking |

|

|

8 |

Low-temperature softness property (-25℃) |

No cracking |

|

|

9 |

Anti-seepage property (0.8Mpa/35mm, 4h) |

No seepage |

|

|

10 |

Impermeability (0.3Mpa, 120min) |

impermeable |

|

|

11 |

Peel strength with |

No treatment |

1.5 |

|

Immersion treatment |

1.0 |

||

|

Sediment Contaminated the surface |

1.0 |

||

|

UV treatment |

1.0 |

||

|

Thermal ageing treatment |

1.0 |

||

|

12 |

Peel Strength |

No treatment |

0.8 |

|

Immersion treatment |

0.8 |

||

Product Features

1. Low requirements on the base surface, saving construction time. It can be constructed on a damp or even unleveled base surface. No primer or pretreatment is required, which can save construction time and reduce project costs.

2. One layer of waterproofing, two layers of defense. The waterproofing effect is more reliable. This membrane has the advantages of polymer waterproof membrane and self-adhesive membrane, greatly improving the performance of puncture resistance, weather resistance, high and low temperature resistance, self-healing, etc. It has excellent physical properties, stable chemical stability and long service life.

3. The self-adhesive layer can form a unique formula of interpenetrating network with the cement molecular structure, so that the membrane can be bonded to the concrete (still inseparable under long-term immersion in water), effectively controlling the water seepage phenomenon, truly achieving the goal of integrating the waterproof membrane with the main structure, and achieving better waterproof effect.

4. Green, environmentally friendly and safe. No solvents and fuels are required during the construction process, which avoids the fire hazards of environmental pollution and saves energy.

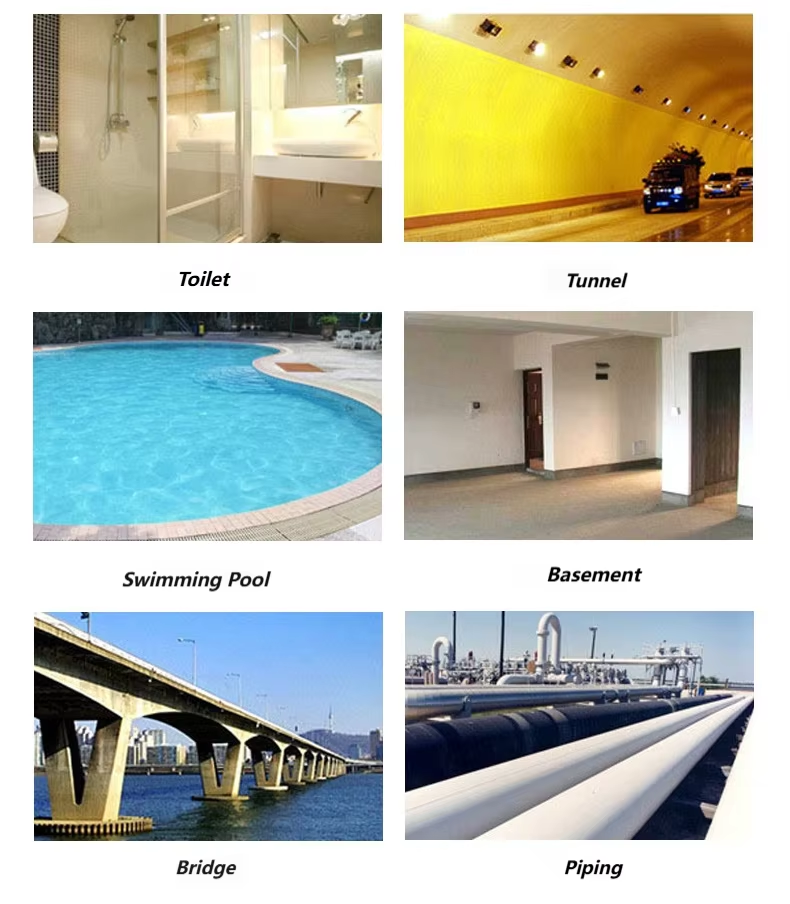

HDPE Membrane Application

1. Traffic engineering: waterproofing and anti-seepage engineering for subways, tunnels, caves, bridges, etc.

2. Construction projects: waterproofing projects such as roofs and basements

3. Water conservancy projects: reservoir dams, cofferdams, canals, artificial lakes and other waterproof and anti-seepage projects

4. Environmental protection projects: landfills, sewage treatment plants, metallurgy, chemical plants and other waterproofing and anti-seepage projects

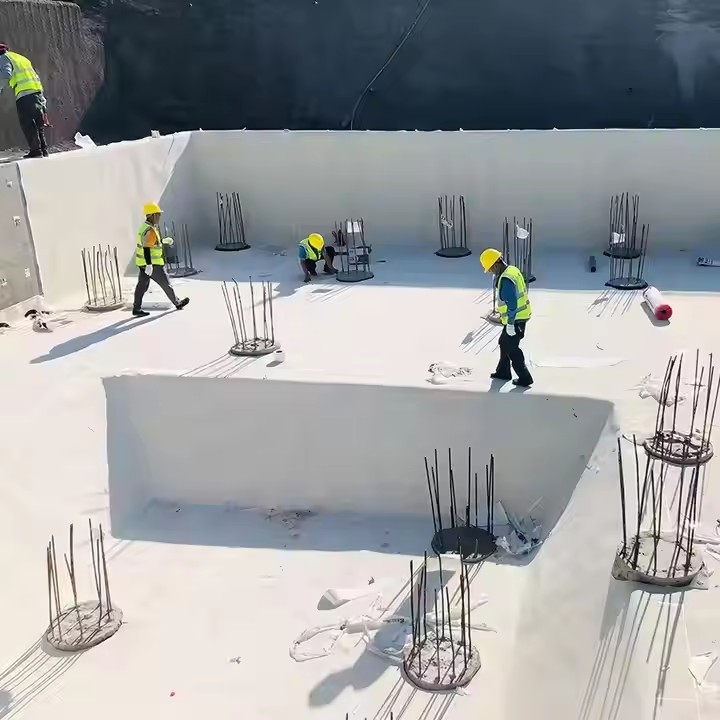

TPO Membrane Installation

Construction method

1. Methods:

The pre-laying reverse bonding construction process is adopted. This waterproof construction method is to pre-lay the waterproof membrane on the flat cushion layer or the vertical enclosure structure before the main structure is constructed. After the waterproof membrane is laid or fixed, concrete is poured on the surface of the waterproof membrane or the inner side of the waterproof layer of the enclosure structure. The polymer self-adhesive film reacts chemically with the cast-in-place concrete to form a strong bond between the waterproof layer and the structural layer, thereby achieving the effect of waterproofing and anti-seepage.

2. Process:

Plane: clean the base → mark the line → lay the waterproof membrane → overlap → tie the steel bars → pour concrete

Facade: clean the base surface, draw lines, lay pre-laid reverse-adhesive waterproof membrane → mechanically fix the waterproof membrane, overlap, tie steel bars, and pour concrete.

3. Clean the base surface: remove sharp protrusions on the base layer where the roll material is laid, and remove dust and debris on the base surface.

4. Pile head treatment: Apply two coats of cement-based penetrating crystallization waterproof coating.

5. The procedure for laying the coiled material is: first the nodes, then the large surface; first the far distance, then the near distance

6. Roll material construction: Determine the laying direction of the roll material according to the shape of the base surface, and lay or fix the polymer self-adhesive waterproofing roll material on the base surface. The overlap of the long side of the roll material should not be less than 100mm, and the overlap of the short side should not be less than 100mm.

7. The short side joints of two adjacent rows of coils should be staggered by more than 300mm to avoid overlapping of multiple layers of joints, which may cause uneven pasting of the coils.

8. For damaged parts, the surface must be cleaned and then repaired with self-adhesive membrane, with the overlap width with the surrounding area not less than 100 mm.

9. After the waterproof layer construction is completed, the acceptance work can be carried out, and the subsequent construction process can only be carried out after qualified acceptance.

Packing And Delivery

Packed in roll into PP woven bag.