tpo roofing

TPO Membrane Introduction

TPO Membrane Specification

|

Product Name

|

TPO Membrane roof

|

|

Thickness

|

1.2mm 1.5mm 1.8mm 2.0mm

|

|

Width

|

2m 2.05m 1m

|

|

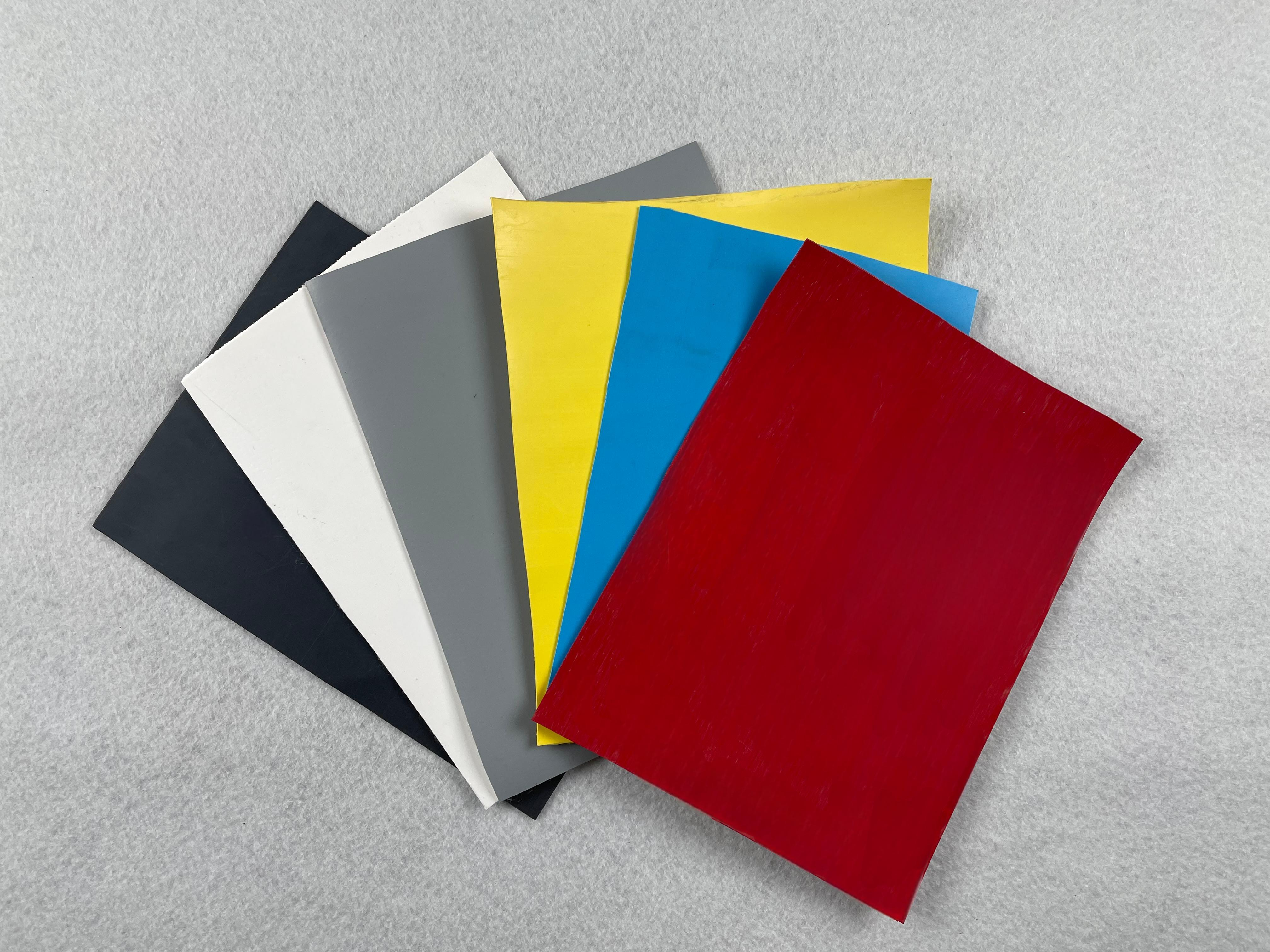

Color

|

White , grey or customized

|

|

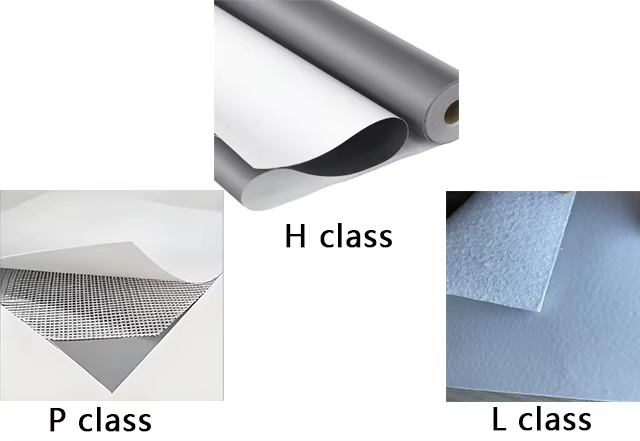

Reinforcement

|

H type, L type ,P type

|

|

Application Method

|

Hot air welding,Mechanical fixation,Cold sticking method

|

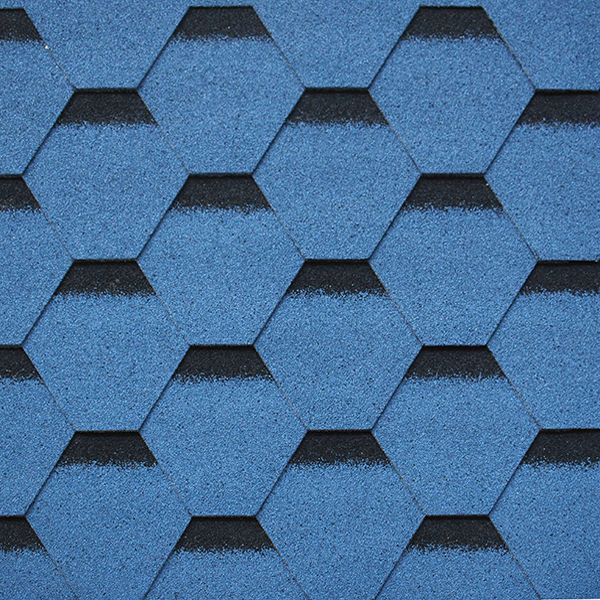

TPO product classification

Customizable Services

Colors can be customized according to requirements

Customizable colloids.

TPO Mrmbarne Standard

|

No. |

Item |

Standard |

|||

|

H |

L |

P |

|||

|

1 |

Thickness of material on the reinforcement/mm ≥ |

- |

- |

0.40 |

|

|

2 |

Tensile Property |

Max Tension/ (N/cm) ≥ |

- |

200 |

250 |

|

Tensile Strength/ Mpa ≥ |

12.0 |

- |

- |

||

|

Elongation Rate/ % ≥ |

- |

- |

15 |

||

|

Elongation Rate at Breaking/ % ≥ |

500 |

250 |

- |

||

|

3 |

Heat treatment dimensional change rate |

2.0 |

1.0 |

0.5 |

|

|

4 |

Flexibility at low temperature |

-40℃, No Cracking |

|||

|

5 |

Unpermeability |

0.3Mpa, 2h, No permeability |

|||

|

6 |

Anti-impact property |

0.5kg.m, No seepage |

|||

|

7 |

Anti-static load |

- |

- |

20kg, No seepage |

|

|

8 |

Peel Strength at joint /(N/mm) ≥ |

4.0 |

3.0 |

3.0 |

|

|

9 |

Right-angle tear strength /(N/mm) ≥ |

60 |

- |

- |

|

|

10 |

Trapeaoidal tear strength /N ≥ |

- |

250 |

450 |

|

|

11 |

Water absorption rate(70℃, 168h) /% ≤ |

4.0 |

|||

|

12 |

Thermal ageing (115℃) |

Time/h |

672 |

||

|

Appearance |

No bundles, cracks,delaminatetion,adhesion or holes |

||||

|

Performance retention rate/ % ≥ |

90 |

||||

|

13 |

Chemical Resistance |

Appearance |

No bundles, cracks,delaminatetion,adhesion or holes |

||

|

Performance retention rate/ % ≥ |

90 |

||||

|

12 |

Artificial climate accelerates ageing |

Time/h |

1500 |

||

|

Appearance |

No bundles, cracks,delaminatetion,adhesion or holes |

||||

|

Performance retention rate/ % ≥ |

90 |

||||

| Note: | |||||

| 1. H type is the Normal TPO membrane | |||||

| 2. L type is the Normal TPO coated with the non-woven fabrics at the back side | |||||

| 3. P type is the Normal TPO reinforced with the fabric mesh | |||||

Product Features

1.NO plasticizer and chlorine element. It is friendly to environment and human body.

2.Resistance to high and low temperature .

3.High tensile strength,tear resistance and root puncture resistance .

4.Smooth surface and light color design,energy saving and no pollution.

5.Hot air welding,it can form a reliable seamless waterproof layer.

TPO Membrane Application

It is mainly applicable to various roof waterproof systems such as industrial and civil buildings and public buildings.

Tunnel, underground pipe gallery, subway, artificial lake, metal steel roof, planted roof, basement, master roof.

P-enhanced waterproof membrane is applicable to the roof waterproof system of mechanical fixation or empty roof pressing;

L backing waterproof membrane is applicable to the roof waterproof system of basic-level full sticking or empty roof pressing;

H homogeneous waterproof membrane is mainly used as flooding material.

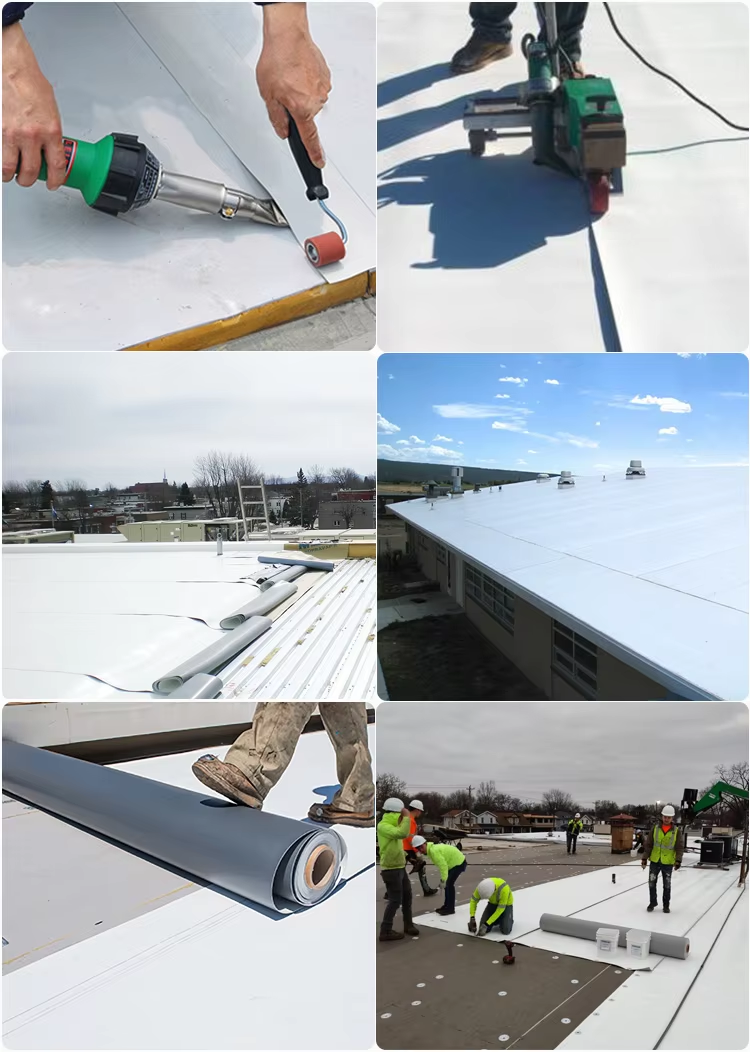

TPO Membrane Installation

TPO empty-laid top-pressed single-layer roofing system

The backing or enhanced waterproof roll is laid on the waterproof base, the adjacent TPO rolls are welded by hot air, and the rolls are laid with concrete paving blocks or pebbles.

Construction points:

1. The base should be dry, flat, and free of floating dust, and the bonding surface of the roll should be dry, clean and pollution-free.

2. TPO roll laying: Lay the roll on the base. After the roll is laid and unfolded, it should be left for 15 to 30 minutes to fully release the internal stress of the roll and avoid wrinkling during welding. Two adjacent rolls are overlapped by 80mm and welded by hot air welding machine.

3. After the rolls are laid and welded, concrete blocks or pebbles should be used to press them in time to avoid wind lifting. Metal strips should be used to fix the surrounding areas of the roof.

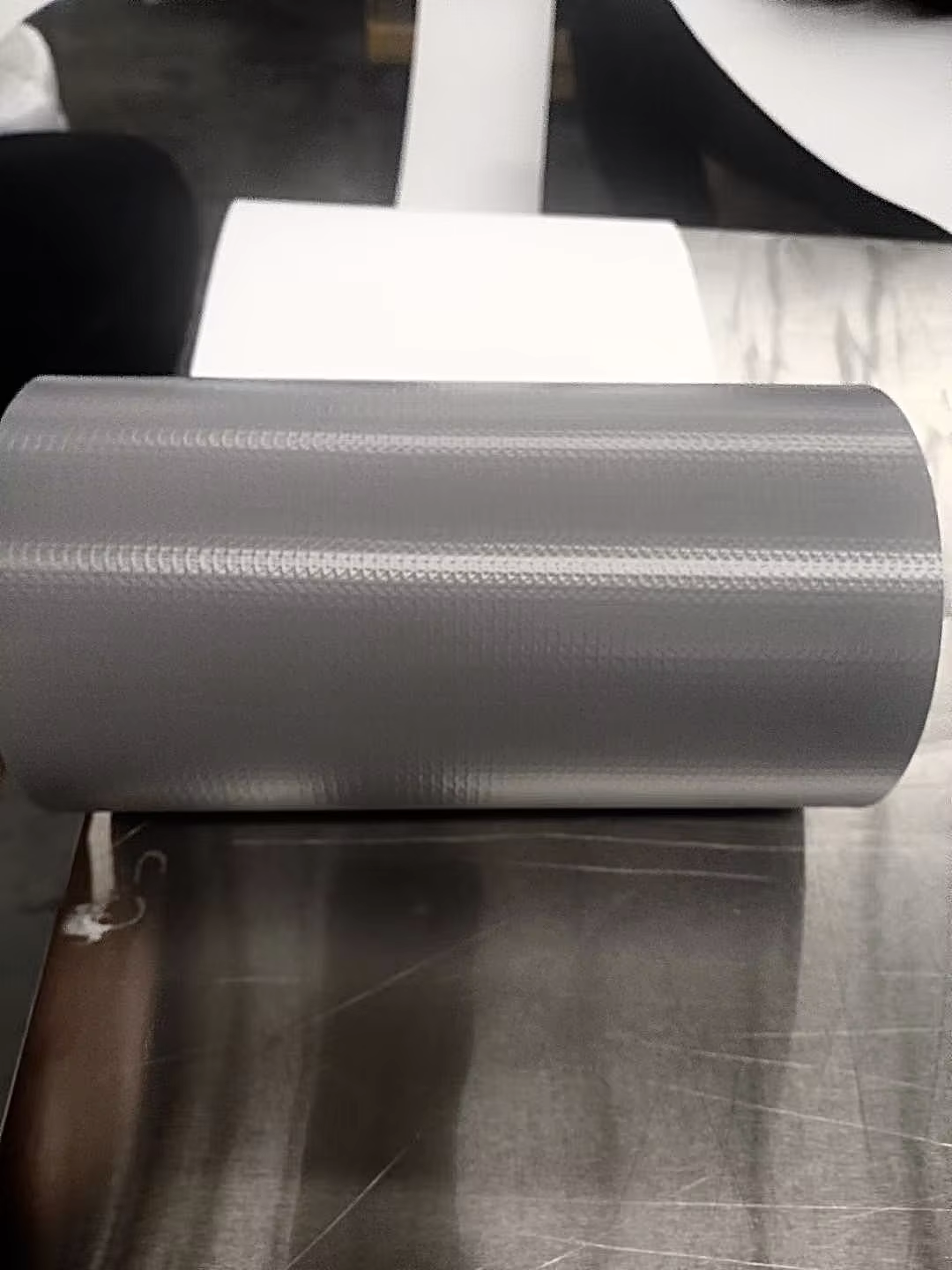

Packing And Delivery

Packed in roll into PP woven bag.