Ixabiso lokufulela nge-tpo eyi-60 mil

Ixabiso lokufulela nge-tpo eyi-60 mil

I-TPO (i-Thermoplastic Polyolefin)i-membrane engangeni manziilula, iguquguquka, kwaye iyasebenza kakuhleisisombululo sophahla. Idume kakhuluUkuxhathisa i-UV, ukuqina kweekhemikhali, kunye nokukhanya kobushushuIipropati, inika ukufakelwa okungenamthungo ngee-seams ezifakwe ubushushu, ezifanelekileyo kuphahla lwezorhwebo, izakhiwo eziluhlaza, kunye nezakhiwo zemizi-mveliso ngelixa ihlangabezana nemigangatho enobuhlobo nokusingqongileyo.

Inkcazelo ye-TPO Membrane

| Ubukhulu | 1.2mm, 1.5mm, 1.8mm, 2mm, okanye eyenziwe ngokwezifiso | ||

| Ububanzi bomqulu | 1m, 2m, okanye eyenziwe ngokwezifiso | ||

| Ubude bomqulu | 15m/roll, 20m/roll, 25m/roll okanye eyenziwe ngokwezifiso. | ||

| Ukuba iveziwe | Iveziwe okanye ayivezwanga. | ||

| Umbala | mhlophe, ngwevu, okanye eyenziwe ngokwezifiso. | ||

| Imigangatho | I-ASTM/GB | ||

I-TPO Mrmbarne Standard

| Hayi. | Into | Umgangatho | |||

| H | L | P | |||

| 1 | Ubukhulu bezinto ezikwi-reinforcement/mm ≥ | - | - | 0.40 | |

| 2 | Ipropati yokuThatha | Uxinzelelo oluphezulu/ (N/cm) ≥ | - | 200 | 250 |

| Amandla okuThamba/ iMpa ≥ | 12.0 | - | - | ||

| Izinga lobude/ % ≥ | - | - | 15 | ||

| Izinga lobude xa liqhekeka/ % ≥ | 500 | 250 | - | ||

| 3 | Izinga lotshintsho lobukhulu bonyango lobushushu | 2.0 | 1.0 | 0.5 | |

| 4 | Ukuguquguquka kubushushu obuphantsi | -40℃, Akukho kuqhekeka | |||

| 5 | Ukungavumi ukugquma | 0.3Mpa, iiyure ezi-2, Akukho kungena kwamanzi | |||

| 6 | Ipropati yokulwa nefuthe | 0.5kg.m, Akukho manzi aphumayo | |||

| 7 | Umthwalo ochasene nokuqina | - | - | 20kg, Akukho kuphuma kwamanzi | |

| 8 | Amandla okuKhuhla kwilungu /(N/mm) ≥ | 4.0 | 3.0 | 3.0 | |

| 9 | Amandla okukrazula ngekona yasekunene /(N/mm) ≥ | 60 | - | - | |

| 10 | Amandla eTrapeaoidal iinyembezi /N ≥ | - | 250 | 450 | |

| 11 | Izinga lokufunxwa kwamanzi (70℃, 168h) /% ≤ | 4.0 | |||

| 12 | Ukuguga okushushu (115℃) | Ixesha/iyure | 672 | ||

| Inkangeleko | Akukho ziqhuma, imifantu, i-delamination, ukunamathela okanye imingxunya | ||||

| Izinga lokugcina ukusebenza/ % ≥ | 90 | ||||

| 13 | Ukumelana neekhemikhali | Inkangeleko | Akukho ziqhuma, imifantu, i-delamination, ukunamathela okanye imingxunya | ||

| Izinga lokugcina ukusebenza/ % ≥ | 90 | ||||

| 12 | Imozulu yokwenziwa ikhawulezisa ukuguga | Ixesha/iyure | 1500 | ||

| Inkangeleko | Akukho ziqhuma, imifantu, i-delamination, ukunamathela okanye imingxunya | ||||

| Izinga lokugcina ukusebenza/ % ≥ | 90 | ||||

| Phawula: | |||||

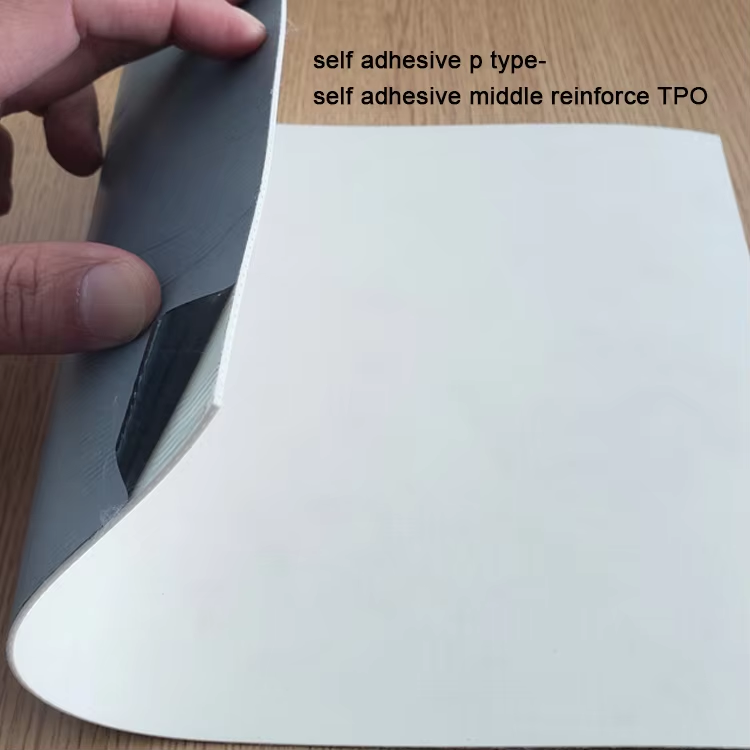

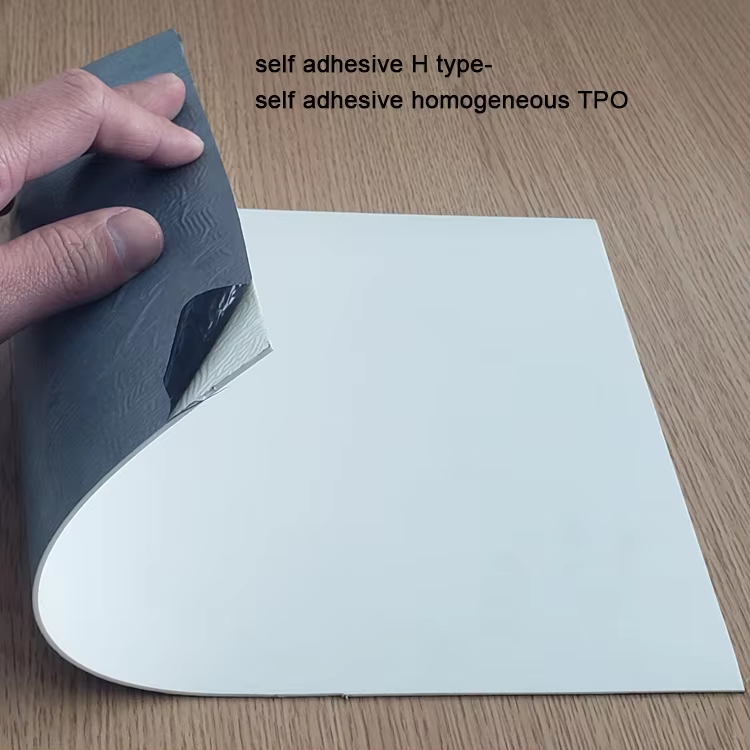

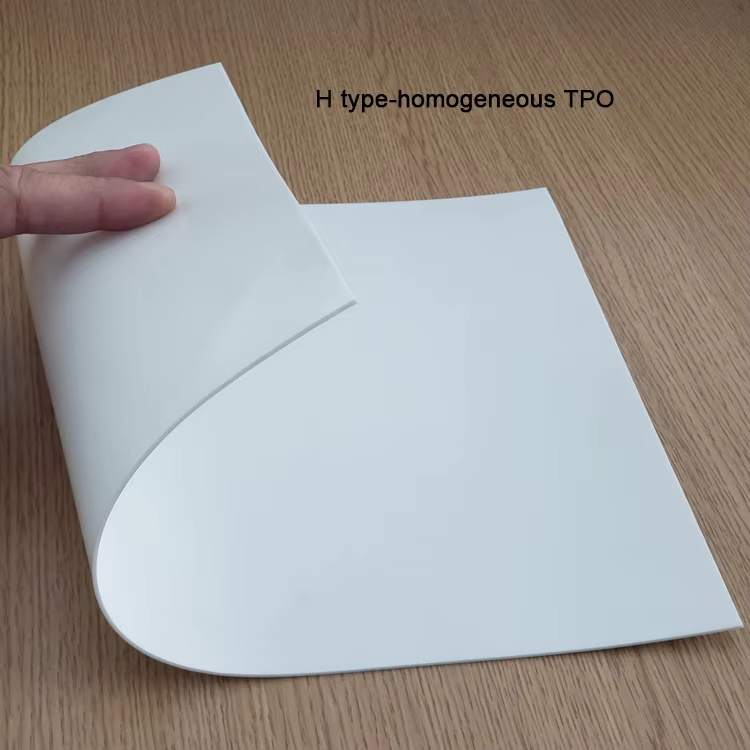

| 1. Uhlobo lwe-H yi-membrane ye-TPO eqhelekileyo | |||||

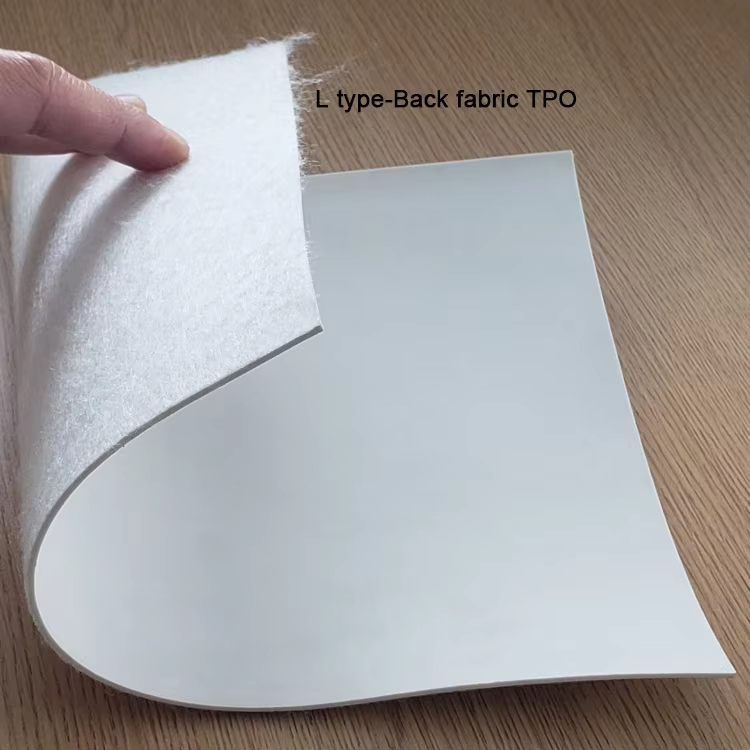

| 2. Uhlobo lwe-L yi-Normal TPO egqunywe ngamalaphu angalukwanga ngasemva | |||||

| 3. Uhlobo lwe-P yi-Normal TPO eqiniswe nge-lap mesh | |||||

Iimpawu zeMveliso

1. Inamandla okulwa nokwaluphala, amandla aphezulu okuxinana kunye nobude obuphezulu;

2. Inokumelana okuhle kakhulu nemozulu kunye nokuguquguquka kobushushu obuphantsi. Ii-seams ezidityanisiweyo zakhiwe nge-heat welding ukwenza umaleko ongenamanzi oqinileyo nothembekileyo;

3. Isebenza kakuhle ekucubunguleni nasekusebenziseni izinto ngendlela eyiyo;

4. Ingakhiwa phezu kophahla olumanzi, ingavezwa ngaphandle komaleko okhuselayo, kulula ukuyakha, ayinangcoliseko, kwaye ifanelekile kakhulu njengomaleko ongangeni manzi wophahla olulula ukonga amandla;

5. I-TPO engangeni manzi ephuculweyo inomaleko welaphu le-polyester fiber embindini, ofaneleke ngakumbi kwiinkqubo zophahla ezilungisiweyo ngoomatshini. Emva kokongeza umaleko welaphu le-polyester fiberPhakathi kweengqimba ezimbini zezinto ze-TPO, iipropati zayo zomzimba, amandla okuphuka, ukumelana nokudinwa kunye nokumelana nokubhoboza kunokuphuculwa.

6. Uhlobo lwe-backed TPO manzi oluyi-membrane, ilaphu elikumphezulu ongezantsi we-membrane lenza kube lula ukudibanisa i-membrane ne-base maleko.

7. I-membrane yokuthintela amanzi ye-TPO efanayo inobunkunkqele obuhle kwaye ingacutshungulwa ibe ziimo ezahlukeneyo emva kokufudumeza ukuze ivumelane nendlela yokusebenza kwamaqhuqhuva antsonkothileyo.

Isicelo se-TPO Membrane

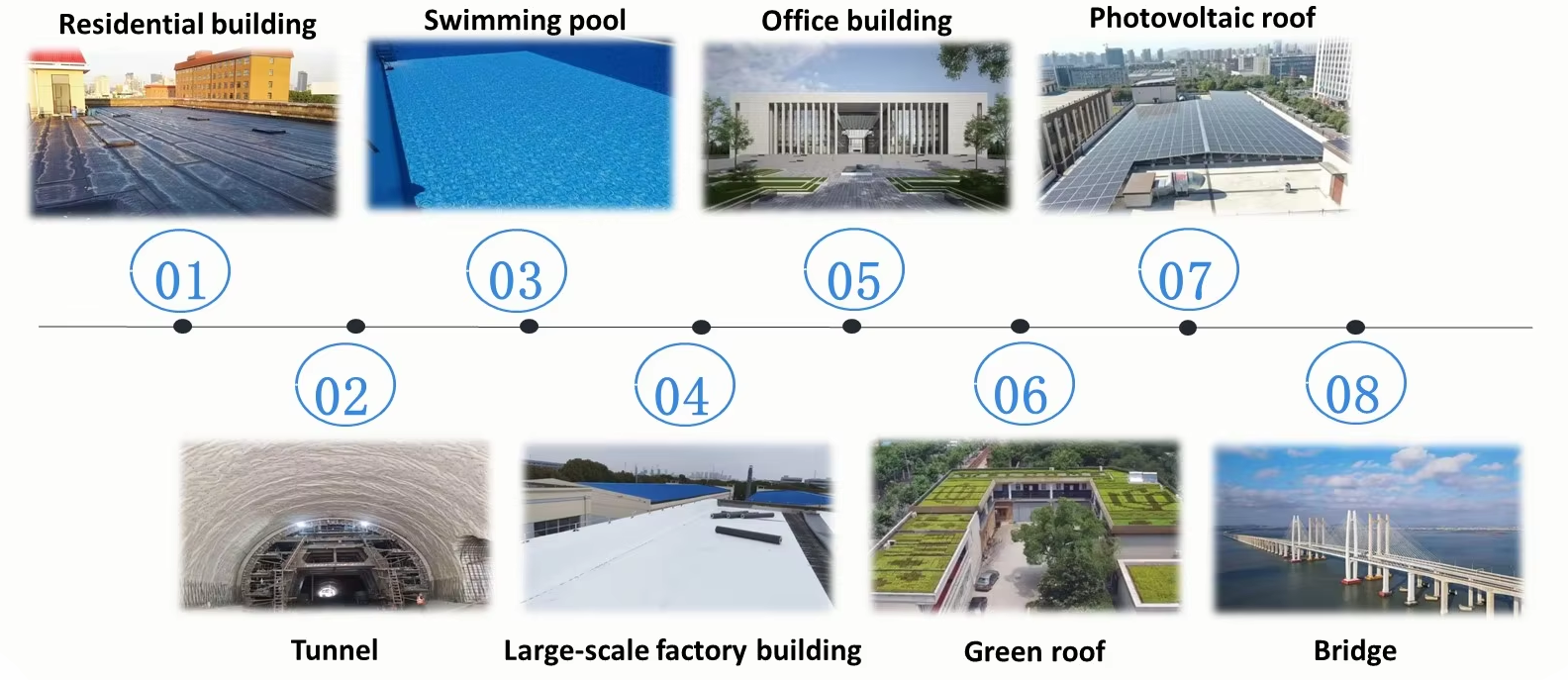

1. Ingafakwa kumaleko okukhusela amanzi ophahla oluvezwe okanye olungavezwanga kwizakhiwo, kunye nokukhusela amanzi angaphantsi komhlaba kwizakhiwo ezilula ukuziguqula;

2. Ilungele ngokukodwa uphahla lwesakhiwo sentsimbi ekhaphukhaphu, kwaye yeyona nto ingangeni manzi ekhethwayo kuphahla lwezityalo ezinkulu zoshishino, izakhiwo zikawonke-wonke, njl.njl.;

3. Ingasetyenziswa nakwiiprojekthi ezingangeni manzi nezingenamanzi ezifana neendawo zokugcina amanzi okusela, izindlu zangasese, amagumbi angaphantsi komhlaba, iitonela, iindawo zokugcina ukutya okuziinkozo, iindlela ezingaphantsi komhlaba, iindawo zokugcina amanzi, njl.

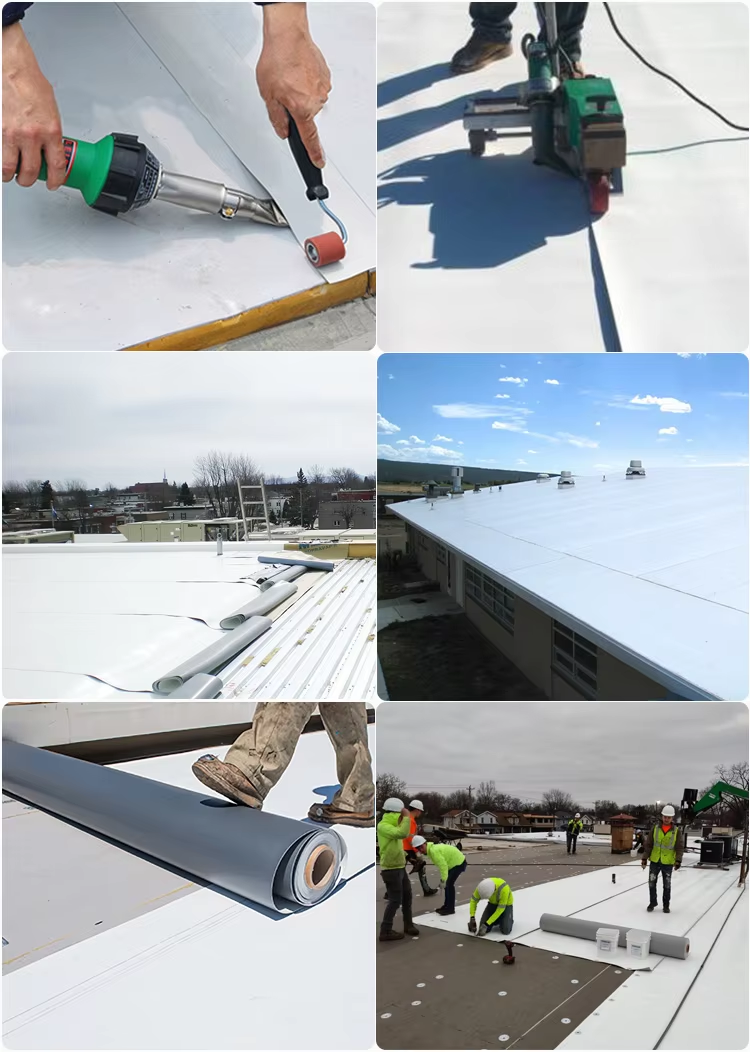

Ukufakwa kweNkumba yeTPO

Iindawo zokwakha:

1. Ubukhulu bepleyiti yentsimbi erhabaxa njengomaleko osisiseko kufuneka bube≥0.75mm, kwaye kufuneka ibe nonxibelelwano oluthembekileyo nesakhiwo esiphambili. Unxibelelwano lwepleyiti yentsimbi kufuneka lube bushelelezi kwaye luqhubeke, lungaphumi nanye imingxunya ebukhali. Isiseko sekhonkrithi kufuneka sibe sithi tyaba, somile, kwaye singabi naziphene ezifana neenyosi kunye nemingxunya.

2. Ukubeka iiroli ze-TPO ngaphambi kwexesha: Emva kokuba iiroli zibekwe zaza zavulwa, mazibekwe imizuzu eli-15 ukuya kwengama-30 ukuze kukhululwe ngokupheleleyo uxinzelelo lwangaphakathi lweeroli kwaye kuthintelwe ukushwabana ngexesha lokuwelda.

3. Lungisa umqulu osezantsi ngoomatshini: Izinto ezifakelweyo mazibekwe ngokuthe tye nangokulinganayo, kwaye isithuba phakathi kwezinto ezifakelweyo masihlangabezane neemfuno zoyilo. Izinto ezifakelweyo ezijikeleze uphahla kunye nendawo yekona mazibe nkulu ngakumbi.

4. Ukuwelda emoyeni oshushu: Umqulu ophezulu ugubungela izibophelelo zoomatshini zomqulu ongezantsi ukuze wenze ukugqubana okungaphantsi kwe-120mm. Umatshini wokuwelda ozenzekelayo usetyenziselwa ukuwelda okufanayo, kwaye ububanzi bokuwelda abungaphantsi kwe-40mm. Ukugqubana okungcolileyo komqulu kufuneka kucocwe ngaphambi kokuba kugqunywe.

5. Ukulungiswa kwee-node ezineenkcukacha: Ngeenkcukacha ezinje ngeekona, iingcambu zepayipi, kunye nee-skylights, iindawo ezenziwe kwangaphambili ze-TPO okanye ii-TPO flashing membranes ezingaqiniswanga zisetyenziswa njengeeleya ezingangeni manzi, kwaye kusetyenziswa i-hot air welding kunye neeleya ephambili engangeni manzi. Isiphelo se-TPO membrane ethe nkqo siqiniswa ngoomatshini nge-metal double-mouth strip, kwaye ekugqibeleni sivalwe nge-sealant.

Ukupakisha kunye nokuHanjiswa

Ipakishwe kwi-roll kwibhegi elukiweyo ye-PP.