i-gaf tpo 60 mil

i-gaf tpo 60 mil

I-TPO (i-Thermoplastic Polyolefin)i-membrane engangeni manzi iyi-kulula, kuyaguquguquka, futhi konga amandlaisixazululo sophahla. Saziwa kakhuluUkumelana ne-UV, ukuqina kwamakhemikhali, kanye nokukhanya kokushisaNjengoba inezakhiwo, inikeza ukufakwa okungenamthungo ngemithungo ehlanganisiwe ngokushisa, ilungele uphahla lwezentengiselwano, izakhiwo eziluhlaza, kanye nezakhiwo zezimboni ngenkathi ihlangabezana nezindinganiso ezinobungani nemvelo.

Ukucaciswa kwe-TPO Membrane

| Ubukhulu | 1.2mm, 1.5mm, 1.8mm, 2mm, noma ngokwezifiso | ||

| Ububanzi bokugoqa | 1m, 2m, noma ngokwezifiso | ||

| Ubude bokugoqa | 15m/roll, 20m/roll, 25m/roll noma ngokwezifiso. | ||

| Uma kuvezwa | Okuveziwe noma Okungaveziwe. | ||

| Umbala | okumhlophe, okumpunga, noma okwenziwe ngokwezifiso. | ||

| Amazinga | I-ASTM/GB | ||

I-TPO Mrmbarne Standard

| Cha. | Into | Okujwayelekile | |||

| H | L | P | |||

| 1 | Ubukhulu bezinto eziqinisiwe/mm ≥ | - | - | 0.40 | |

| 2 | Impahla Eqinile | Ukuqina Okuphezulu/ (N/cm) ≥ | - | 200 | 250 |

| Amandla Okudonsa/ Mpa ≥ | 12.0 | - | - | ||

| Izinga Lobude/ % ≥ | - | - | 15 | ||

| Izinga Lobude Ekuqhekekeni/ % ≥ | 500 | 250 | - | ||

| 3 | Izinga lokushintsha kobukhulu bokwelashwa kokushisa | 2.0 | 1.0 | 0.5 | |

| 4 | Ukuguquguquka ekushiseni okuphansi | -40℃, Akukho ukuqhekeka | |||

| 5 | Ukungangeni kwamanzi | 0.3Mpa, amahora ama-2, Akukho ukungena kwamanzi | |||

| 6 | Impahla yokulwa nomthelela | 0.5kg.m, Akukho ukuvuza kwamanzi | |||

| 7 | Umthwalo ophikisana nokuma | - | - | 20kg, Akukho ukuvuza kwamanzi | |

| 8 | Amandla Okuhluba emalungeni /(N/mm) ≥ | 4.0 | 3.0 | 3.0 | |

| 9 | Amandla okudabuka kwe-engeli yesokudla /(N/mm) ≥ | 60 | - | - | |

| 10 | Amandla e-Trapeaoidal izinyembezi /N ≥ | - | 250 | 450 | |

| 11 | Izinga lokumuncwa kwamanzi (70℃, 168h) /% ≤ | 4.0 | |||

| 12 | Ukuguga Okushisayo (115℃) | Isikhathi/ihora | 672 | ||

| Ukubukeka | Akukho zinqwaba, imifantu, ukuhlukanisa, ukunamathela noma imigodi | ||||

| Izinga lokugcina ukusebenza/ % ≥ | 90 | ||||

| 13 | Ukumelana namakhemikhali | Ukubukeka | Akukho zinqwaba, imifantu, ukuhlukanisa, ukunamathela noma imigodi | ||

| Izinga lokugcina ukusebenza/ % ≥ | 90 | ||||

| 12 | Isimo sezulu sokwenziwa sisheshisa ukuguga | Isikhathi/ihora | 1500 | ||

| Ukubukeka | Akukho zinqwaba, imifantu, ukuhlukanisa, ukunamathela noma imigodi | ||||

| Izinga lokugcina ukusebenza/ % ≥ | 90 | ||||

| Qaphela: | |||||

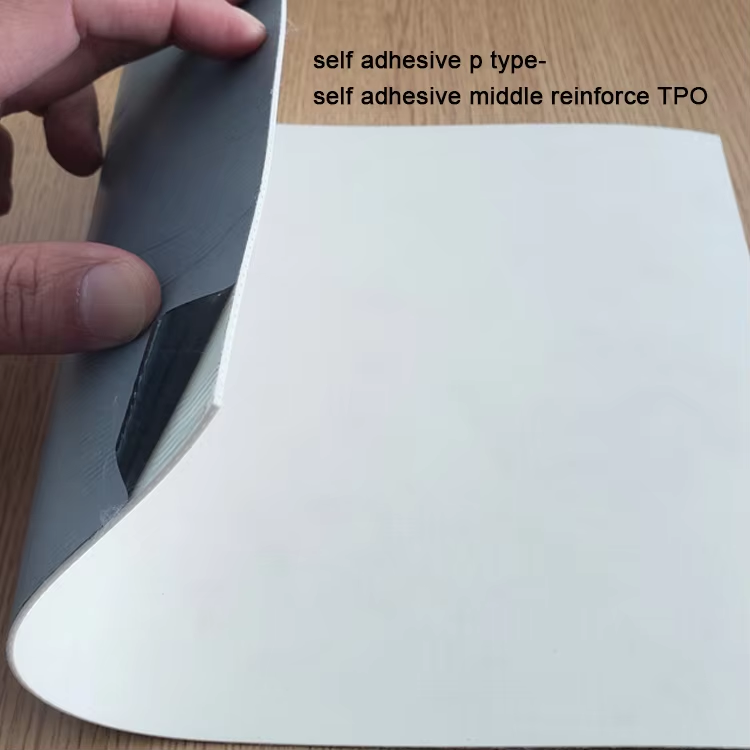

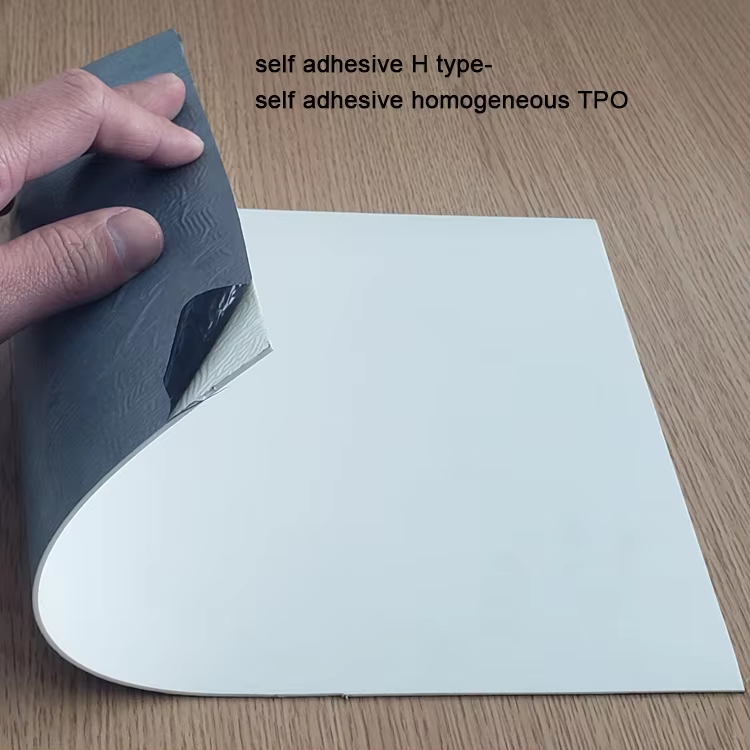

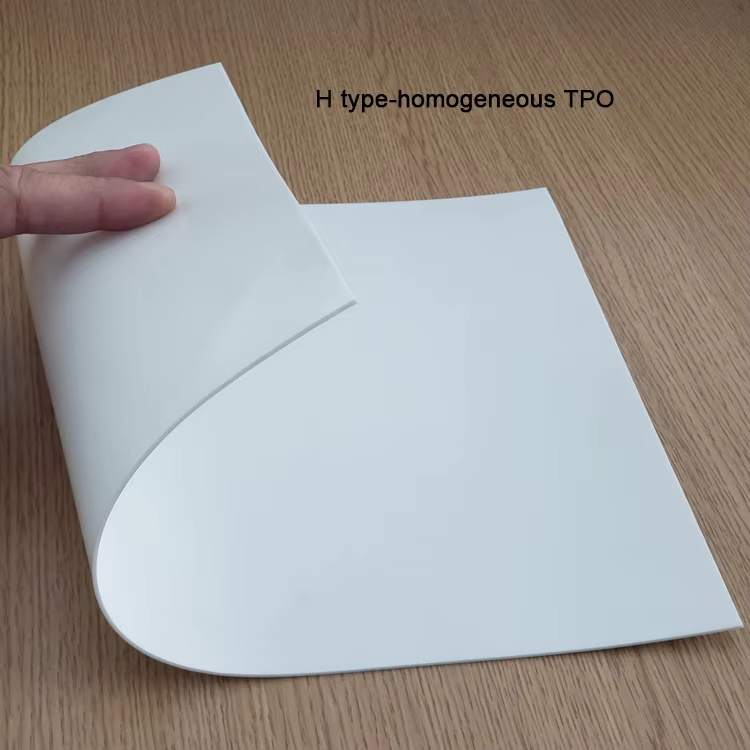

| 1. Uhlobo lwe-H luyi-membrane ye-TPO evamile | |||||

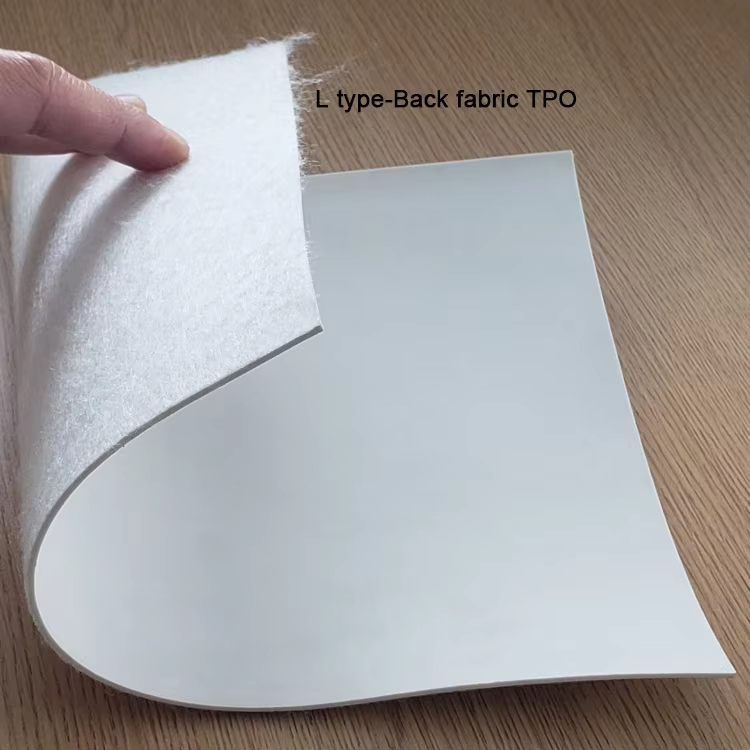

| 2. Uhlobo lwe-L luyi-Normal TPO embozwe ngezindwangu ezingalukiwe ngemuva | |||||

| 3. Uhlobo lwe-P luyi-TPO evamile eqiniswe nge-lamb mesh | |||||

Izici Zomkhiqizo

1. Inamandla okulwa nokuguga, amandla aphezulu okubamba kanye nobude obuphezulu;

2. Inokumelana okuhle kakhulu nesimo sezulu kanye nokuguquguquka kwezinga lokushisa eliphansi. Iminyango ehambisanayo yakhiwe ngokushisela ukushisa ukuze kwakheke ungqimba olungangeni manzi oluqinile noluthembekile;

3. Isebenza kahle ekucubunguleni kanye nezakhiwo zemishini;

4. Ingakhiwa ophahleni olumanzi, ingavezwa ngaphandle kwesendlalelo esivikelayo, kulula ukuyakha, ayinangcoliso, futhi ifaneleka kakhulu njengesendlalelo esingangeni manzi sophahla olulula olugcina amandla;

5. I-TPO engangeni manzi ethuthukisiwe inesendlalelo sendwangu ye-polyester fiber phakathi, efaneleka kakhulu ezinhlelweni zophahla ezilungisiwe ngomshini. Ngemva kokufaka isendlalelo sendwangu ye-polyester fiberPhakathi kwezingqimba ezimbili zezinto ze-TPO, izakhiwo zayo zomzimba, amandla okuphuka, ukumelana nokukhathala kanye nokumelana nokubhoboza kungathuthukiswa.

6. Uhlobo lwe-Back TPO manzi olwenza i-membrane ingangenisi amanzi, indwangu engaphansi kwe-membrane yenza i-membrane ibe lula ukubopha nesendlalelo sesisekelo.

7. I-TPO engangenisi manzi i-membrane efanayo inokwakheka okuhle futhi ingacutshungulwa ibe yizimo ezahlukahlukene ngemva kokushisa ukuze ivumelane nomkhuba wama-node ayinkimbinkimbi.

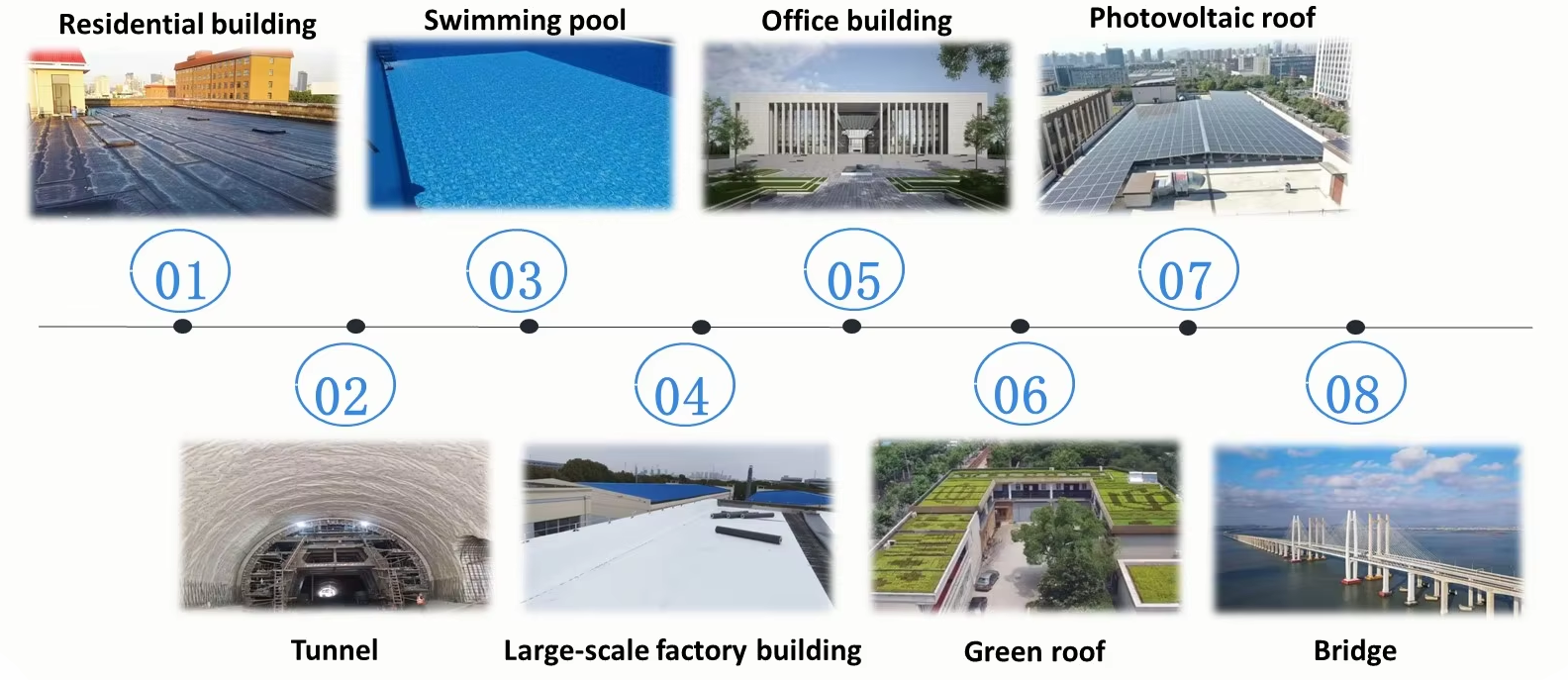

Isicelo se-TPO Membrane

1. Ingasetshenziswa engqimbeni yokuvikela uphahla oluveziwe noma olungaveziwe lwezakhiwo, kanye nokuvikela ulwelwesi olungaphansi komhlaba lwezakhiwo okulula ukuziguqula;

2. Ifaneleka kakhulu ophahleni lwesakhiwo sensimbi elula, futhi iyinto engangeni manzi ekhethwayo ophahleni lwezitshalo ezinkulu zezimboni, izakhiwo zomphakathi, njll.;

3. Ingasetshenziswa futhi kumaphrojekthi angangeni manzi futhi angangeni umswakama njengezindawo zokugcina amanzi okuphuza, izindlu zangasese, amagumbi angaphansi komhlaba, imigudu, izindawo zokugcina okusanhlamvu, imigwaqo engaphansi komhlaba, izindawo zokugcina amanzi, njll.

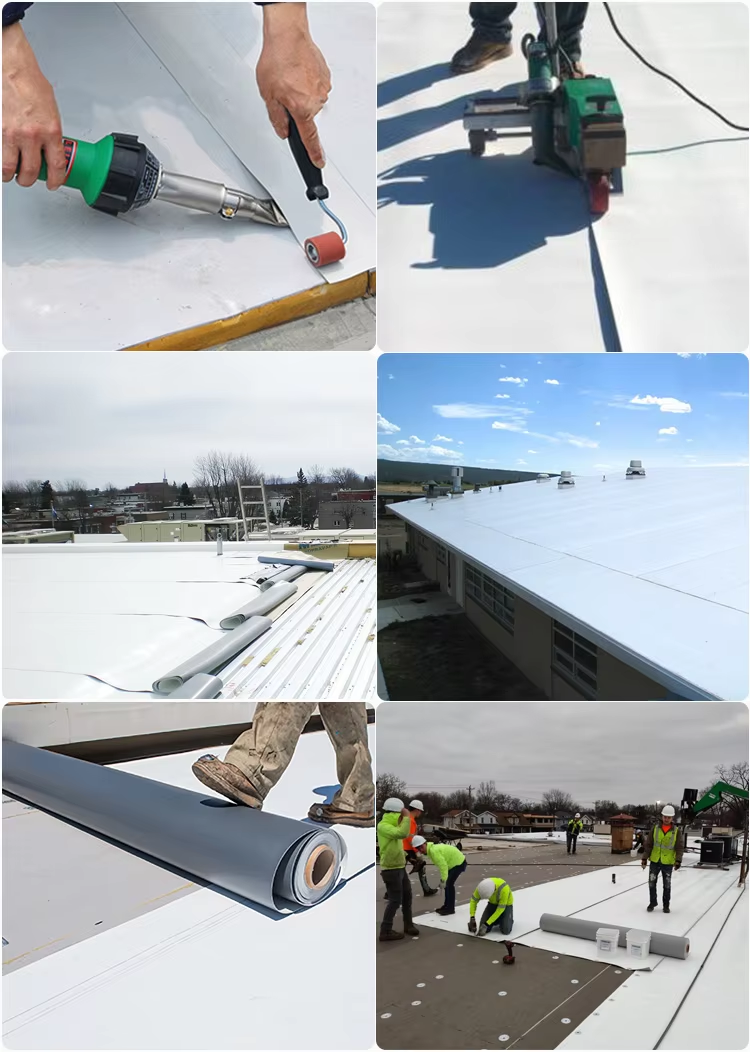

Ukufakwa kwe-TPO Membrane

Izindawo zokwakha:

1. Ubukhulu bepuleti lensimbi elihlanganisiwe njengesendlalelo sesisekelo kufanele bube≥0.75mm, futhi kumele ibe nokuxhumana okuthembekile nesakhiwo esiyinhloko. Ukuxhumana kwepuleti lensimbi kufanele kube bushelelezi futhi kuqhubeke, kungabi nama-protrusion abukhali. Isisekelo sekhonkrithi kufanele sibe sicaba, somile, futhi singenazo iziphambeko ezifana nama-honeycombs kanye nemifantu.

2. Ukubekwa kusengaphambili kwemiqulu ye-TPO: Ngemva kokuba imiqulu ibekwe futhi ivuliwe, kufanele ibekwe imizuzu eyi-15 kuya kwengama-30 ukuze ikhulule ngokuphelele ukucindezeleka kwangaphakathi kwemiqulu futhi igweme ukushwabana ngesikhathi sokushisela.

3. Lungisa umqulu ongezansi ngomshini: Izinto ezihlanganisiwe kufanele zihlelwe ziqonde futhi zilingane, futhi isikhala phakathi kwezinto ezihlanganisiwe kufanele sihlangabezane nezidingo zomklamo. Izinto ezihlanganisiwe ezizungeze uphahla kanye nendawo ekhoneni kufanele zibe ziningi kakhulu.

4. Ukushisela umoya oshisayo: Umqulu ongaphezulu umboza izinamathiselo zemishini zomqulu ongezansi ukuze kwakheke ukugoqana okungengaphansi kuka-120mm. Umshini wokushisela ozenzakalelayo usetshenziselwa ukushisela okufanayo, kanti ububanzi bokushisela bungengaphansi kuka-40mm. Ukugoqana okungcolile komqulu kufanele kuhlanzwe ngaphambi kokushisela.

5. Ukucutshungulwa kwama-node okuningiliziwe: Ukuze uthole imininingwane efana namakhona, izimpande zamapayipi, kanye nama-skylight, izingxenye ezenziwe nge-TPO noma ama-flashing membrane angaqiniswanga e-TPO asetshenziswa njengezendlalelo ezingangeni manzi, kanti ukushisela umoya oshisayo kusetshenziswa nesendlalelo esiyinhloko esingangeni manzi. Isiphetho se-TPO membrane eqondile siqiniswa ngomshini nge-strip yensimbi enomlomo ophindwe kabili, bese ekugcineni sivalwa nge-sealant.

Ukupakisha Nokulethwa

Ipakishwe nge-roll esikhwameni esilukiwe se-PP.