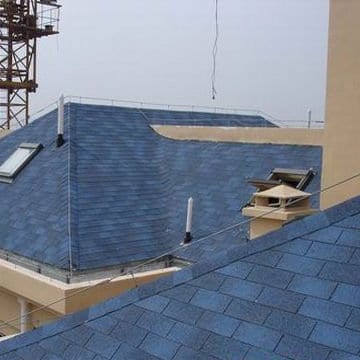

inkqubo yophahla lwe-tpo

inkqubo yophahla lwe-tpo

Inkcazelo ye-TPO Membrane

| Igama lemveliso | Uphahla lwe-TPO Membrane |

| Ubukhulu | 1.2mm 1.5mm 1.8mm 2.0mm |

| Ububanzi | 2m 2.05m 1m |

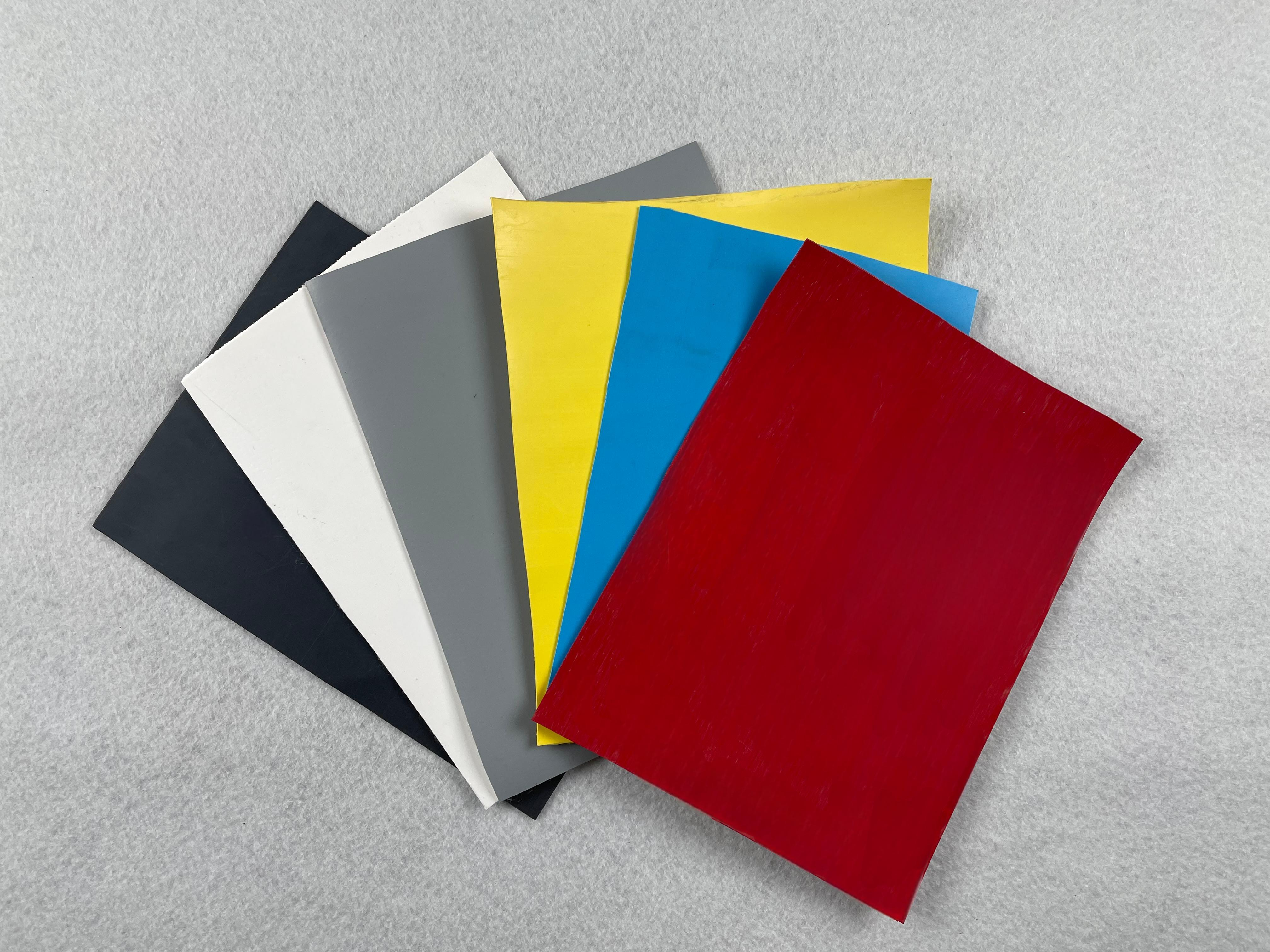

| Umbala | Mhlophe, ngwevu okanye eyenziwe ngokwezifiso |

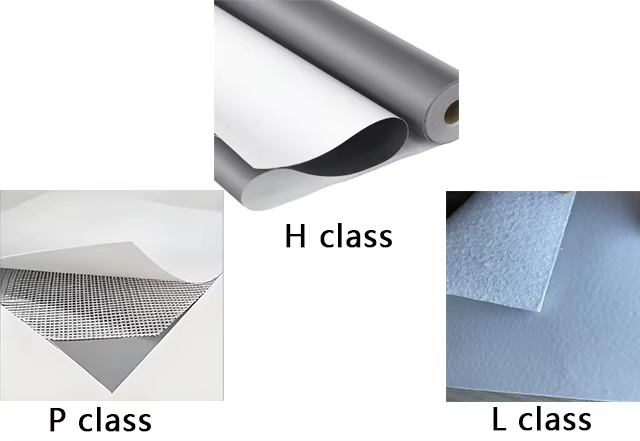

| Uqinisekiso | Uhlobo lwe-H, uhlobo lwe-L, uhlobo lwe-P |

| Indlela yesicelo | Ukuwelda komoya oshushu, Ukulungiswa koomatshini, Indlela yokuncamathela ebandayo |

Uhlu lwemveliso ye-TPO

Iinkonzo Ezinokulungiselelwa Ngokwezifiso

Imibala ingenziwa ngokwezifisongokweemfuno

Ii-colloids ezinokwenziwa ngokwezifiso.

I-TPO Mrmbarne Standard

| Hayi. | Into | Umgangatho | |||

| H | L | P | |||

| 1 | Ubukhulu bezinto ezikwi-reinforcement/mm ≥ | - | - | 0.40 | |

| 2 | Ipropati yokuThatha | Uxinzelelo oluphezulu/ (N/cm) ≥ | - | 200 | 250 |

| Amandla okuThamba/ iMpa ≥ | 12.0 | - | - | ||

| Izinga lobude/ % ≥ | - | - | 15 | ||

| Izinga lobude xa liqhekeka/ % ≥ | 500 | 250 | - | ||

| 3 | Izinga lotshintsho lobukhulu bonyango lobushushu | 2.0 | 1.0 | 0.5 | |

| 4 | Ukuguquguquka kubushushu obuphantsi | -40℃, Akukho kuqhekeka | |||

| 5 | Ukungavumi ukugquma | 0.3Mpa, iiyure ezi-2, Akukho kungena kwamanzi | |||

| 6 | Ipropati yokulwa nefuthe | 0.5kg.m, Akukho manzi aphumayo | |||

| 7 | Umthwalo ochasene nokuqina | - | - | 20kg, Akukho kuphuma kwamanzi | |

| 8 | Amandla okuKhuhla kwilungu /(N/mm) ≥ | 4.0 | 3.0 | 3.0 | |

| 9 | Amandla okukrazula ngekona yasekunene /(N/mm) ≥ | 60 | - | - | |

| 10 | Amandla eTrapeaoidal iinyembezi /N ≥ | - | 250 | 450 | |

| 11 | Izinga lokufunxwa kwamanzi (70℃, 168h) /% ≤ | 4.0 | |||

| 12 | Ukuguga okushushu (115℃) | Ixesha/iyure | 672 | ||

| Inkangeleko | Akukho ziqhuma, imifantu, i-delamination, ukunamathela okanye imingxunya | ||||

| Izinga lokugcina ukusebenza/ % ≥ | 90 | ||||

| 13 | Ukumelana neekhemikhali | Inkangeleko | Akukho ziqhuma, imifantu, i-delamination, ukunamathela okanye imingxunya | ||

| Izinga lokugcina ukusebenza/ % ≥ | 90 | ||||

| 12 | Imozulu yokwenziwa ikhawulezisa ukuguga | Ixesha/iyure | 1500 | ||

| Inkangeleko | Akukho ziqhuma, imifantu, i-delamination, ukunamathela okanye imingxunya | ||||

| Izinga lokugcina ukusebenza/ % ≥ | 90 | ||||

| Phawula: | |||||

| 1. Uhlobo lwe-H yi-membrane ye-TPO eqhelekileyo | |||||

| 2. Uhlobo lwe-L yi-Normal TPO egqunywe ngamalaphu angalukwanga ngasemva | |||||

| 3. Uhlobo lwe-P yi-Normal TPO eqiniswe nge-lap mesh | |||||

Iimpawu zeMveliso

1. AKUKHO plasticizer kunye ne-chlorine element. Ilungele okusingqongileyo kunye nomzimba womntu.

2. Ukumelana nobushushu obuphezulu nobuphantsi.

3. Amandla aphezulu okuxinana, ukumelana nokukrazula kunye nokumelana nokubhoboza iingcambu.

4.Uyilo oluthambileyo lombala kunye nombala okhanyayo, ukonga amandla kwaye akukho ngcoliseko.

5. Ukuwelda komoya oshushu, kunokwenza umaleko othembekileyo ongenamthungo ongangeni manzi.

Isicelo se-TPO Membrane

Isebenza ikakhulu kwiinkqubo ezahlukeneyo zophahla ezingangeni manzi ezifana nezakhiwo zoshishino nezoluntu kunye nezakhiwo zikawonke-wonke.

Umjelo, igalari yemibhobho engaphantsi komhlaba, umzila ongaphantsi komhlaba, ichibi lokwenziwa, uphahla lwentsimbi yesinyithi, uphahla olutyaliweyo, isiseko, uphahla olukhulu.

I-membrane engangeni manzi ephuculweyo ye-P iyasebenza kwinkqubo engangeni manzi yophahla yokufakelwa koomatshini okanye ukucinezelwa kophahla olungenanto;

I-L backing proof membrane iyasebenza kwinkqubo yophahla engangeni manzi yokunamathela ngokupheleleyo kwinqanaba elisisiseko okanye ukucinezela uphahla olungenanto;

I-membrane engangeni manzi ene-H efanayo isetyenziswa kakhulu njengezinto zokukhukula.

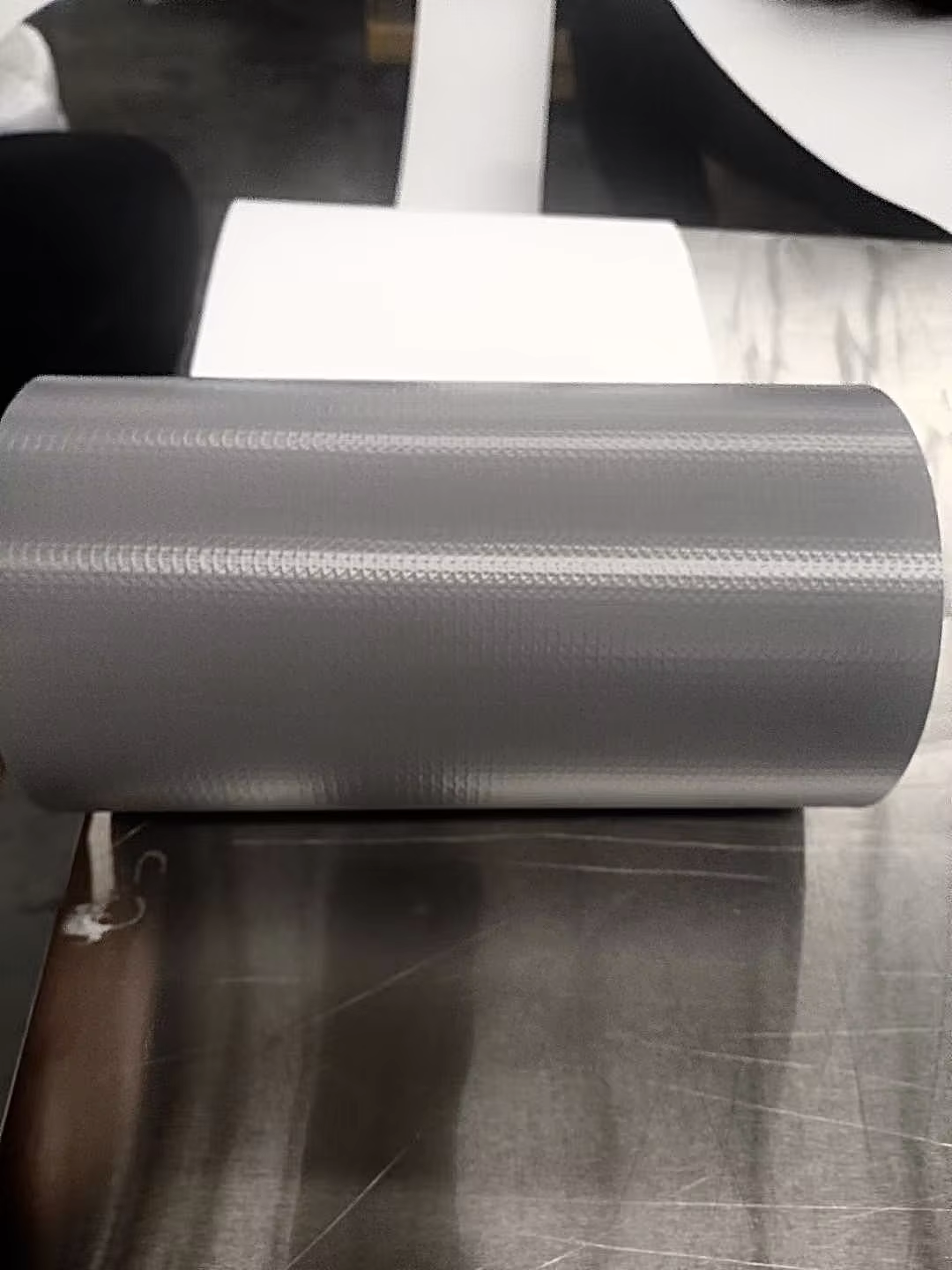

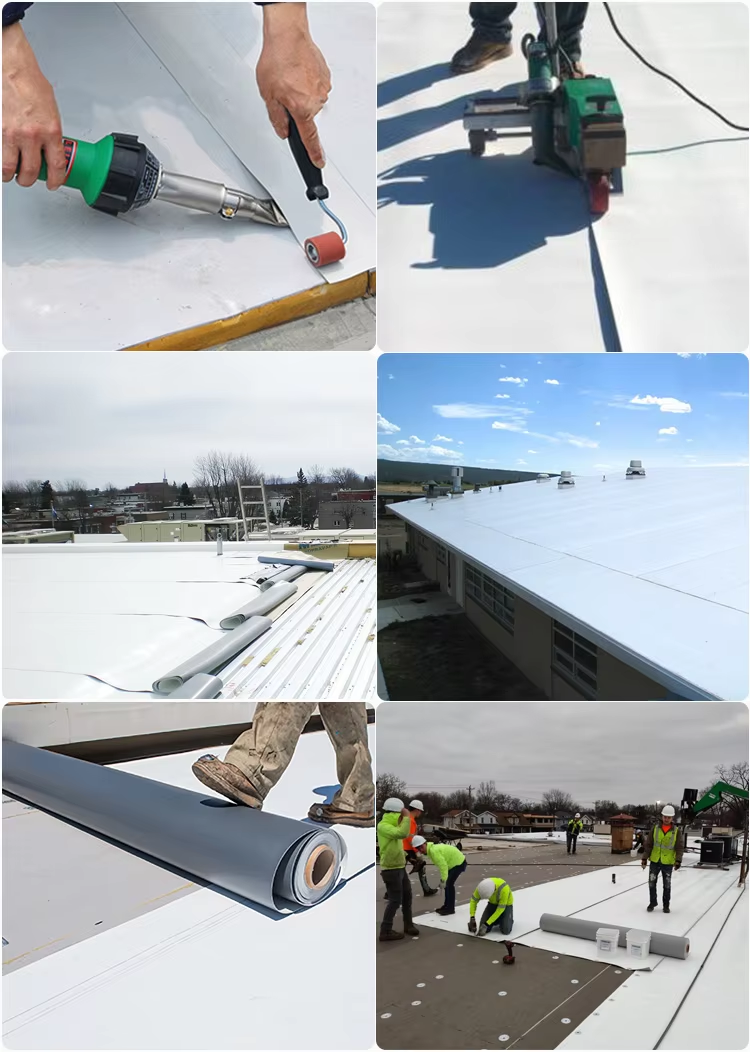

Ukufakwa kweNkumba yeTPO

Inkqubo yophahla olunemaleko enye engenanto ebekwe phezulu ecinezelwe phezulu ye-TPO

Iroli engasemva okanye eyongeziweyo engangeni manzi ibekwa kwisiseko esingangeni manzi, imiqulu ye-TPO ekufutshane idityaniswa ngumoya oshushu, kwaye imiqulu ibekwa ngeebhloko zekhonkrithi okanye iingqalutye.

Iindawo zokwakha:

1. Isiseko masibe somile, sithe tyaba, singenalo uthuli oludadayo, kwaye umphezulu wokubopha weroli kufuneka wome, ucoceke kwaye ungabi nangcoliseko.

2. Ukubeka i-TPO roll: Beka i-roll kwisiseko. Emva kokuba i-roll ibekwe yaza yavuleka, kufuneka ishiywe imizuzu eli-15 ukuya kwengama-30 ukuze ikhulule ngokupheleleyo uxinzelelo lwangaphakathi lwe-roll kwaye iphephe ukushwabana ngexesha lokuwelda. Ii-roll ezimbini ezikufutshane zijikeleziswa nge-80mm kwaye zifakwe i-welding ngomatshini wokuwelda oshushu.

3. Emva kokuba imiqolo ibekwe kwaye idityanisiwe, kufuneka kusetyenziswe iibhloko zekhonkrithi okanye iingqalutye ukuze zicinezelwe ngexesha elifanelekileyo ukuze kuthintelwe ukuphambuka komoya. Imicu yesinyithi mayisetyenziswe ukulungisa iindawo ezijikelezileyo zophahla.

Ukupakisha kunye nokuHanjiswa

Ipakishwe kwi-roll kwibhegi elukiweyo ye-PP.